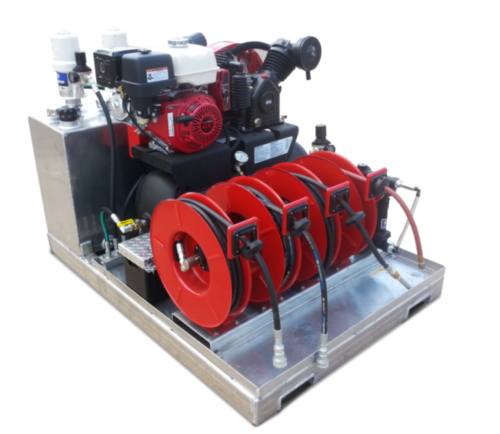

If you’re in the market for a grapple truck or attachment, you can’t beat industry-leading Rotobec grapples. Rotobec launched its revolutionary rotating hydraulic system in the forestry industry. Later, the company expanded its product offerings to include recycling, waste handling, railroad maintenance, and construction and bulk material handling.

Which grapple will work best for you? Rotobec has a wide selection of grapples designed for specific industries and job applications.

Forestry & Logging

Excavators, material handlers, and log loaders need tough grapples that can adapt to various situations. If you’re looking for something versatile, Rotobec’s Log Grapples, Combination Grapples, and Rotobec Power Attachments fit the bill. Rotobec’s Pulpwood Grapples and Butt’n Top Grapples load and unload trucks efficiently.

Industrial Jobs

Industrial grapples handle a variety of materials in any environment imaginable. Rotobec’s Clamshell Buckets are available in multiple sizes and configurations. The Demolition Power Attachment Grapple is built with thicker, stronger steel. Rotobec’s Pipe & Pole Handing Series Grapples safely handle utility poles and gas lines.

Waste Handling

Rotobec offers grapple attachments for each step of the waste handling and waste removal process, with specialized units for trash, compaction, sorting/demolition, and waste collection. Plus, they offer multi-purpose, and waste collection grapples that make roadside pickup and storm cleanup quicker and more efficient.

Scrap Metal

If it isn’t tough, you don’t want to use it for scrap metal. Rotobec is an industry leader in durable, tough, innovative products for scrap metal handling. Their Orange Peel Grapple has a fully guarded, hose-less cylinder design that reduces the risk of hydraulics damage. The Demolition RPA’s 360-degree rotation allows for more flexibility in motion than traditional dangle style rotation grapples.

Railway Operations

Need to move railroad ties? Look no further than Rotobec’s rail grapples. The Tie Bundle Grapple can handle 5-9 tie-wide bundles, and the Loose Tie Grapple helps collect and move ties without bringing shale along.

Storm Chasers

Hurricanes, tornadoes, severe storms, and floods can cause catastrophic damage and leave behind an immense amount of debris. Storm chasers need dump trucks outfitted with a versatile, multi-purpose loader and grapple combination that can handle a variety of materials, such as the Rotobec Elite 910 + Waste Collection Grapple.

Authorized Rotobec Dealer

Looking for a do-everything package? Pair a Rotobec loader and grapple with a Ledwell Dump Truck for a powerful machine that’ll get the job done.

As an authorized Rotobec dealer with the quickest turnaround times in the industry, we can build a truck to your specs and ship it out when you need it, where you need it. Learn more.

Contact us to discuss which Rotobec attachment will best meet your needs.