Here in America, we love our pork.

We eat an average of 264 pounds of meat per person each year, and 67 of those pounds are pork products. Back in 1978 when Hanor Company’s roots in commercial pig productions started, the average person ate just 191 pounds of meat per year. As demand for pork grew, so did pork farms across the country.

What started as a single 1000-sow farrow-to-finish operation—which includes all stages of pork production from breeding to market—has expanded to seven states and now sells 1.4 million market hogs each year.

Hanor Company now has farms in Wisconsin, Oklahoma, North Carolina, Iowa, and Illinois, and their genetic breeding program supports an integrated pig production system that processes 9 million pigs annually. Neal Jordan, transportation environmental manager for Hanor Companies in North Carolina, said it simply: “We raise pigs for a living.” Jordan, one of the company’s 650+ employees, has been at Hanor for 20 years.

Raising pigs is anything but simple, though. In July, Hanor veterinarian Jon Tangen told FarmJournal’s Pork that the industry faces global threats like African swine fever and the war in Ukraine with Russia impacting grain prices and thus impacting the cost to raise meat.

Despite global challenges and those that hit closer to home—like inflation, oil prices, and finding and retaining employees—Hanor Companies employees are dedicated to maintaining high standards when it comes to their hogs. Hanor supports the Pork Checkoff’s We Care initiative, which includes acknowledging a farm’s responsibility to produce safe food, protect and promote animal wellbeing, and ensure practices to protect public health.

“It’s of our utmost interest to make sure our pigs are well taken care of the entirety of their lifetime, until we utilize them for a nutritious protein source to feed our neighbors,” Tangen told FarmJournal’s Pork in July.

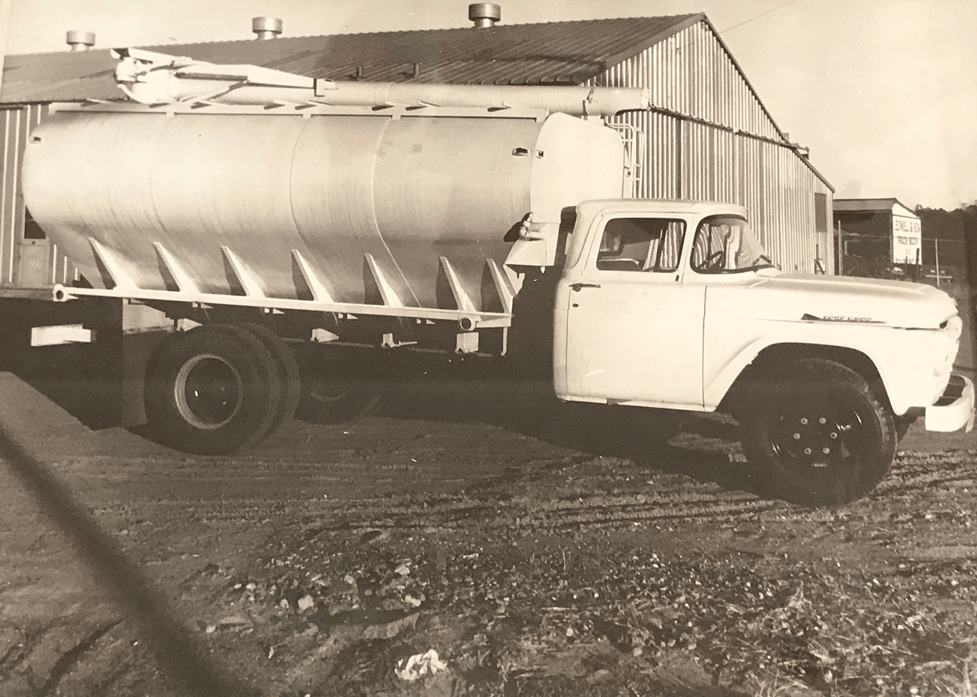

Tough bulk feed trailers with high standards for safety, sanitation and biosecurity are key in the pork industry. And while farms spent roughly 60 percent of the cost of raising pigs on feed in 2017, farmers have seen those prices jump to 70%-80% over the past few years.

That makes efficiency in feed transportation even more important.

“I’ve been here 20 years, and Ledwell bulk feed trailers were here before me,” Jordan said. He said he’s still running a 1996 Ledwell trailer in his fleet. “Usually one that’s pulled every day, 300-400 miles a day, I try to move them out of the fleet in about 12-13 years.”

In North Carolina, Jordan is responsible for managing a fleet of about 10 tractors and 30 trailers. With skyrocketing feed costs, they have to choose transportation equipment that reduces waste and lets them get the most out of their feed.

“Ledwell bulk feed trailers are good equipment,” he said. “They’re reliable, not expensive to maintain. They’re always willing to help. They always make accommodations for what we need.”

Ledwell works with Hanor to customize their stock bulk feed trailer with modifications specific to the needs of Hanor’s farms.

In a business with lots of rough gravel roads that can be harsh on even the best equipment, drivers don’t have time for downtime.

“If we have a major breakdown, Ledwell is normally Johnny-on-the-spot as far as getting us what we need to get the repair done,” Jordan said. Ledwell can respond quickly to those requests because they manufacture more than 80% of their parts in-house, meaning they don’t have to wait on other suppliers.

That’s by design. The Ledwell Made Guarantee, which backs every product, promises swift support that helps you get back to work quickly and tough-built products that last for decades with proper maintenance.

And that’s exactly the kind of equipment that Hanor Company, one of the nation’s premier pork producers, needs to keep producing safe food for our communities.