Ledwell recently announced the expansion of its manufacturing space with the addition of 66,000 square feet to supplement the existing twelve acres of space under roof.

With this significant expansion, Ledwell aims to add new jobs and increase efficiencies by focusing on technological refinements to its production line and engineering.

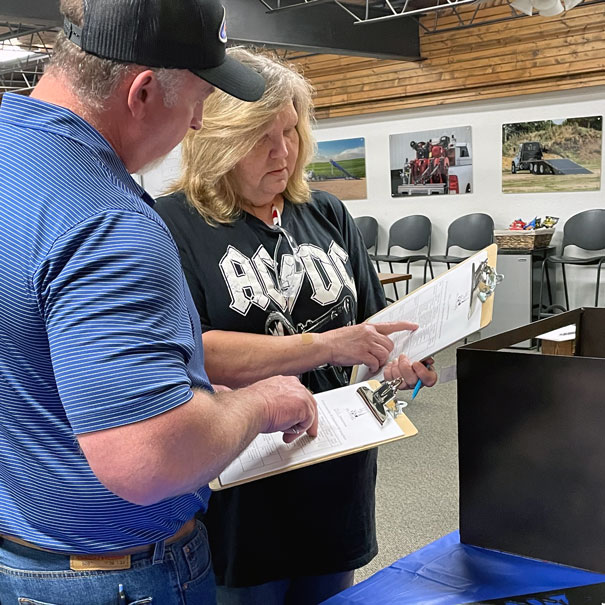

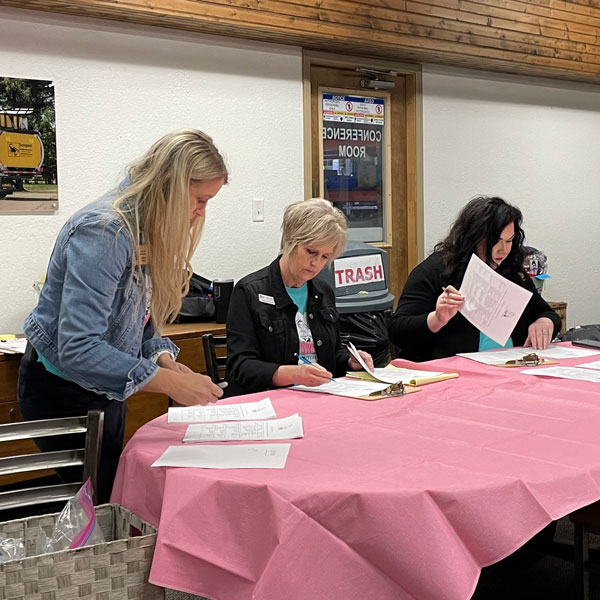

Ledwell hosted a ribbon-cutting event on Thursday, May 18th, 2023, to celebrate. The Ledwell workforce in Texas and members of the community attended the event. The celebration was a testament to the hard work and dedication of the Ledwell team.

The ribbon-cutting ceremony was led by Lesley Ledwell, President, who expressed her gratitude to everyone who has supported the company over the years. “We would not be where we are today without the support of our customers, employees, and community.”

Ledwell is known for meeting customer challenges with innovative solutions. This time, the solution is a brand-new manufacturing facility with endless possibilities. The new facility will offer the flexibility to fabricate and enhance its diverse product offering.