“Our customers farm vegetables, orchards, vineyards—they farm year-round,” said Bobby Creason, President and CEO of Booth Machinery. “We put a high amount of hours on the equipment we provide these folks. It’s always moving. It’s very important that they have their tractors, water trucks, or whatever they need at their fingertips at all times.”

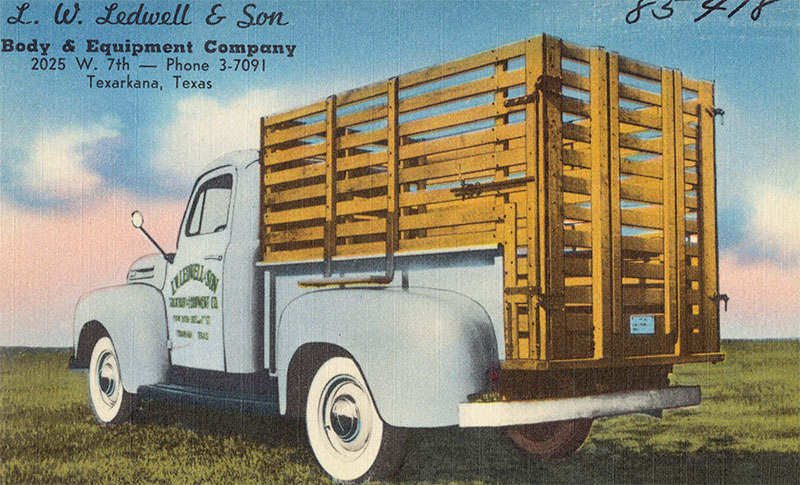

Booth Machinery started as a single location in Yuma, Arizona, more than 30 years ago. It originally opened in the 1940s under the name Caldwell Equipment, and it has served customers in California and Arizona for nearly eight decades. Over the past seven years, Booth Machinery has expanded into seven different counties in California through acquisition.

“Our agricultural customers are running every day of the year,” Bobby said. “This isn’t your typical row crop farm, where they farm part of the year. It’s going all the time.”

He said the COVID-19 pandemic created new and unexpected challenges for his customers.

“Just imagine that you sold lettuce and your main customers are schools and or restaurants,” Bobby said. “One day, you wake up, and those businesses are closed. What do you do? You can’t just change your packaging overnight. That really presented a bit of a challenge for our customers. Some were able to adjust and come out on top.”

One thing is for sure, according to Bobby: the Booth Machinery team stepped up.

“I’m extremely proud of our team for staying in the workplace as essential workers,” he said. “It goes without saying how important ag is to the entire world. It’s not something that could have just stopped. I’m extremely proud of our team and the steps we took to stay open following CDC’s guidance for social distancing and masking.”

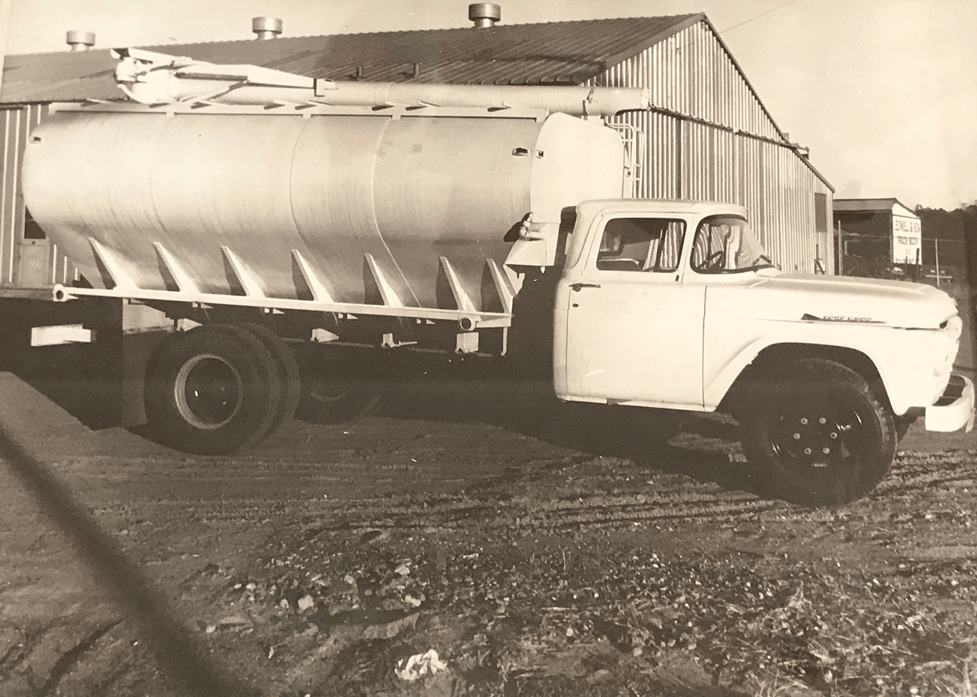

When it comes to agriculture, having dependable equipment, such as water trucks, is crucial.

“One particular challenge our California customers have is drought,” Bobby said. “They have to transfer water, and they also need to be able to get the ground wet to transplant products such as tomatoes. Dust control is also big out here. There are so many things water trucks are used for.”

Bobby said he has been buying Ledwell Water Trucks for 15 years, starting at his previous jobs in Hawaii and Colorado.

“These sales didn’t go through some big fleet manager,” he said. “It has been me personally dealing with Lesley and Steve [Ledwell]. The challenges we face with lead time, quality, and post-sale support—Lesley and Steve have always taken care of me.”

That’s why Ledwell has an excellent reputation in the West, according to Ledwell Regional Manager Mike Brackins. Mike has represented Ledwell in the West for the past two years.

“I remember the first time I visited with Steve,” Mike said. “I’d been on board for a month. There was a minor issue, and he was ready to move heaven and earth to get it fixed. Our service, compared to our competitors, is unparalleled. Ledwell will make it right.”

Booth Machinery both rents and sells Ledwell Water Trucks. Bobby said Ledwell’s tough build and swift support have made a good impression on his customers.

“When we need something, we get it, and we get it fast,” he said. “We feel like we’ve got a lot of up-front support, as well as the parts and service side post-purchase. For some of our parts and service, we’re dependent on the dealers that handle the chassis, but I’ve always appreciated Ledwell’s ability to nudge those folks at times to help get us moving.”

He said there are less expensive water trucks and manufacturers that are closer to the market where they’re needed, but they don’t provide the value and support that Ledwell does.

“A cheap deal to me is only good until you need help, or you need availability, or you need trucks that are built and ready to go,” Bobby said. “Ledwell brings us so much value. We get the right advice up front. We get market intel. We talk about the different options we need on the truck. We get support afterwards, and communication throughout.”

He said the relationship, quality, and immediate support if you do have a problem presents a good value for Booth Machinery.

“The only problem I ever had was not listening to Ledwell and letting me buy the wrong trucks years ago,” Bobby said. “A topic that still comes up from time to time with people who had to work through those challenges.”