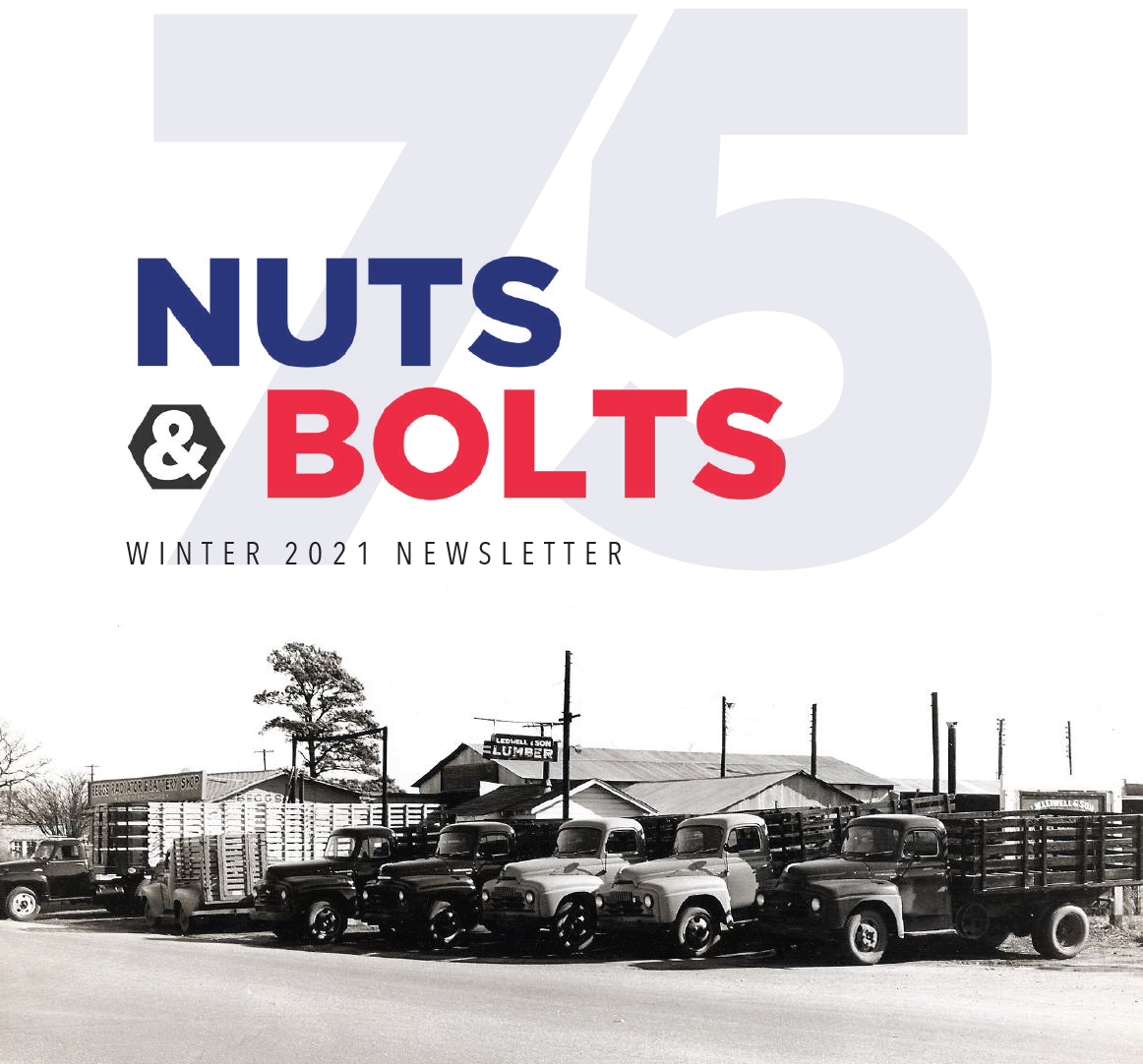

How it started

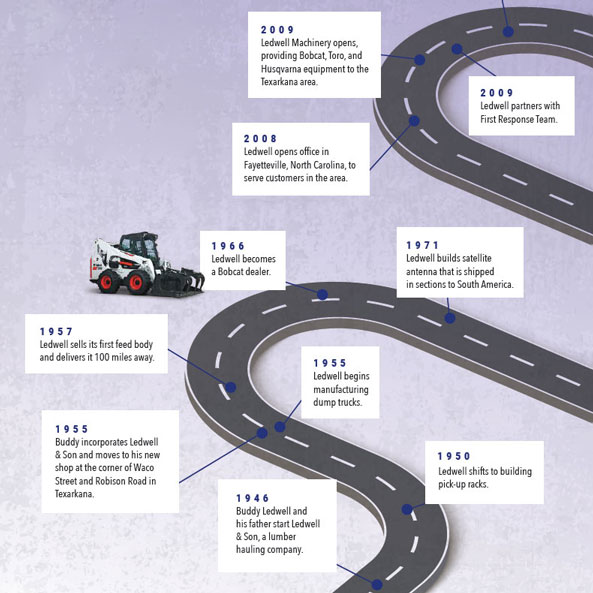

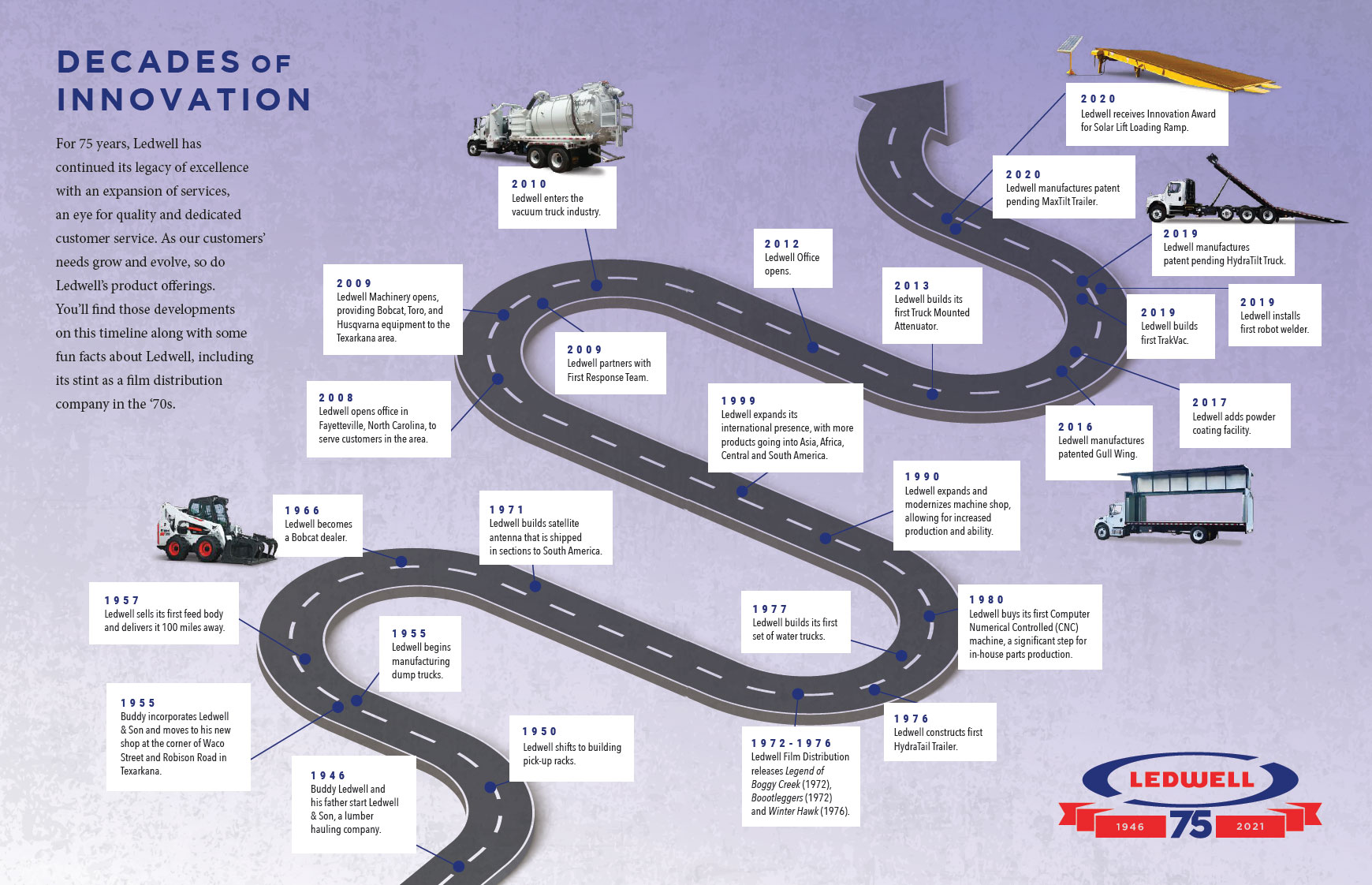

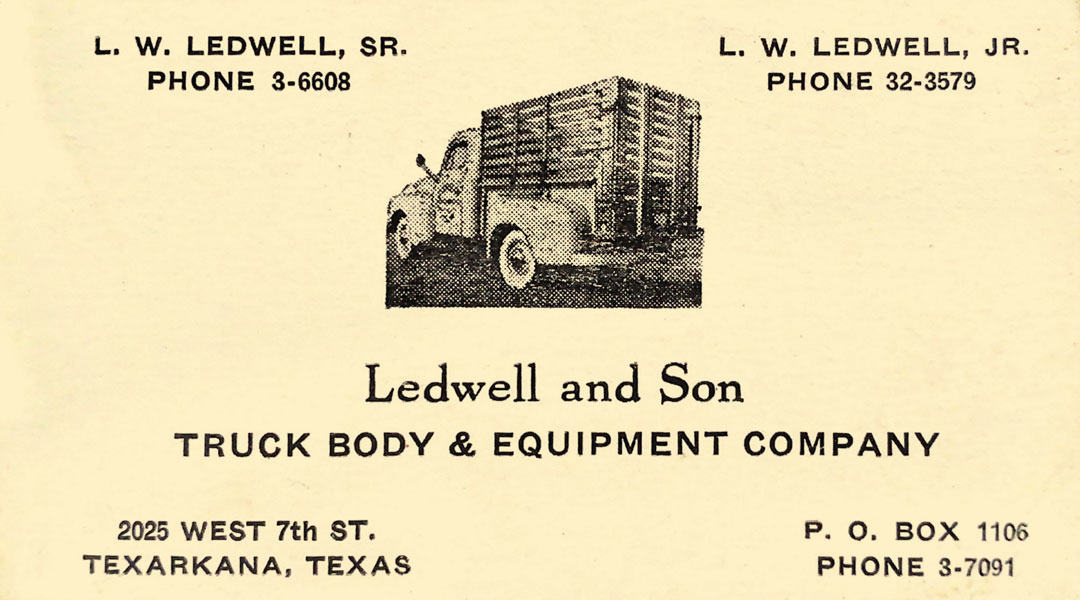

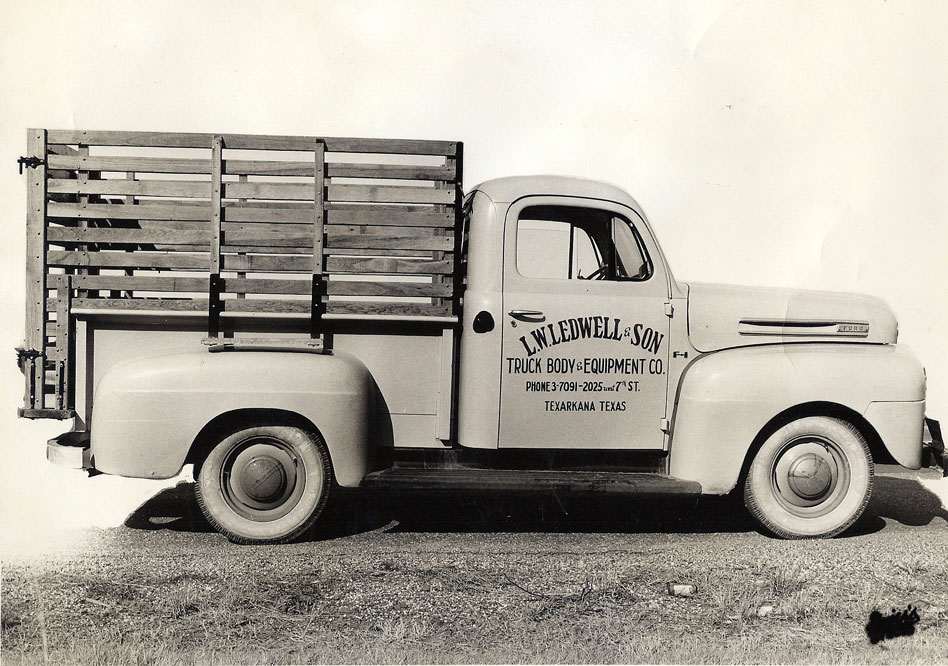

After returning from WWII in 1946, Buddy and his father L.W. Ledwell Sr. started a lumber company called Ledwell & Son in Texarkana, Texas. One day Buddy needed a certain kind of truck trailer to haul lumber, so he rolled up his sleeves and welded the frame he needed to get the job done.

A neighboring farmer saw the trailer and asked, “Where’d you get that? I need one!” So Buddy built it.

Pretty soon, Ledwell & Son had a burgeoning side business building pickup racks and livestock trailers, and it soon became the focus of the operation. When a farmer or a feedlot owner identified a problem with their equipment, Buddy and his father found a way to manufacture a solution.

How it’s going

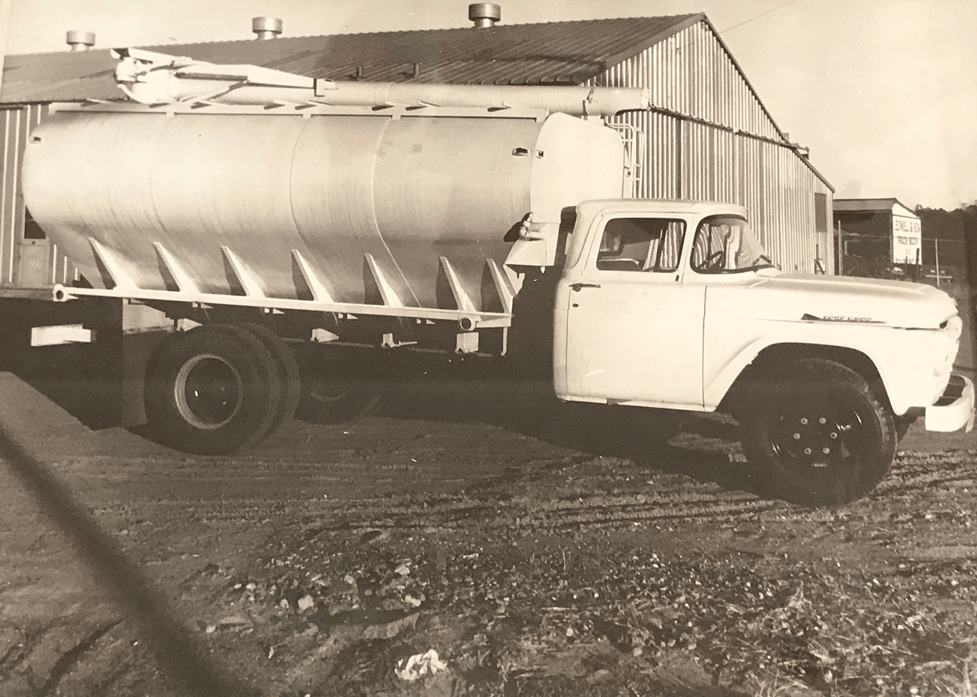

Seventy-five years later, Ledwell builds custom trailers and truck bodies for just about every industry—from water and feed trucks to their own patented hydraulic trailers—for customers all over the world. If a need arises for a truck or trailer to perform a job or haul a particular piece of equipment, Ledwell finds a way to manufacture a solution.

“We build our trucks and trailers to be tough,” said Steve Ledwell.

“Things that are add-ons for other manufacturers, like stronger steel and thicker water tank linings, are standard on our products. With proper care and maintenance, we expect our customers to get decades of service out of our equipment. That’s what ‘Ledwell Made’ means to us.”

The company also prides itself on service and its US-made equipment, with more than 85% of their parts manufactured in-house.

Today, the legacy of the 75-year old business continues under the fourth generation leadership of Buddy’s granddaughter, Lesley Ledwell Dukelow. Ledwell has grown to employ more than 500 workers and has vastly expanded the company’s plant footprint in Texarkana, along with adding a location in Fayetteville, North Carolina.

“The fact that the business has grown to provide so many jobs while still maintaining a family atmosphere is something we’re very proud of,” Dukelow said. “The level of dedication and service that our team provides our customers has only gotten stronger over the last 75 years.”