If you mentioned Shane Miller at Ledwell, the most likely response is, “Who is Shane?”.

As most Ledwell employees call him, Lefty attended Texarkana College to pursue a welding certification. He used that knowledge when he began his career 20 years ago.

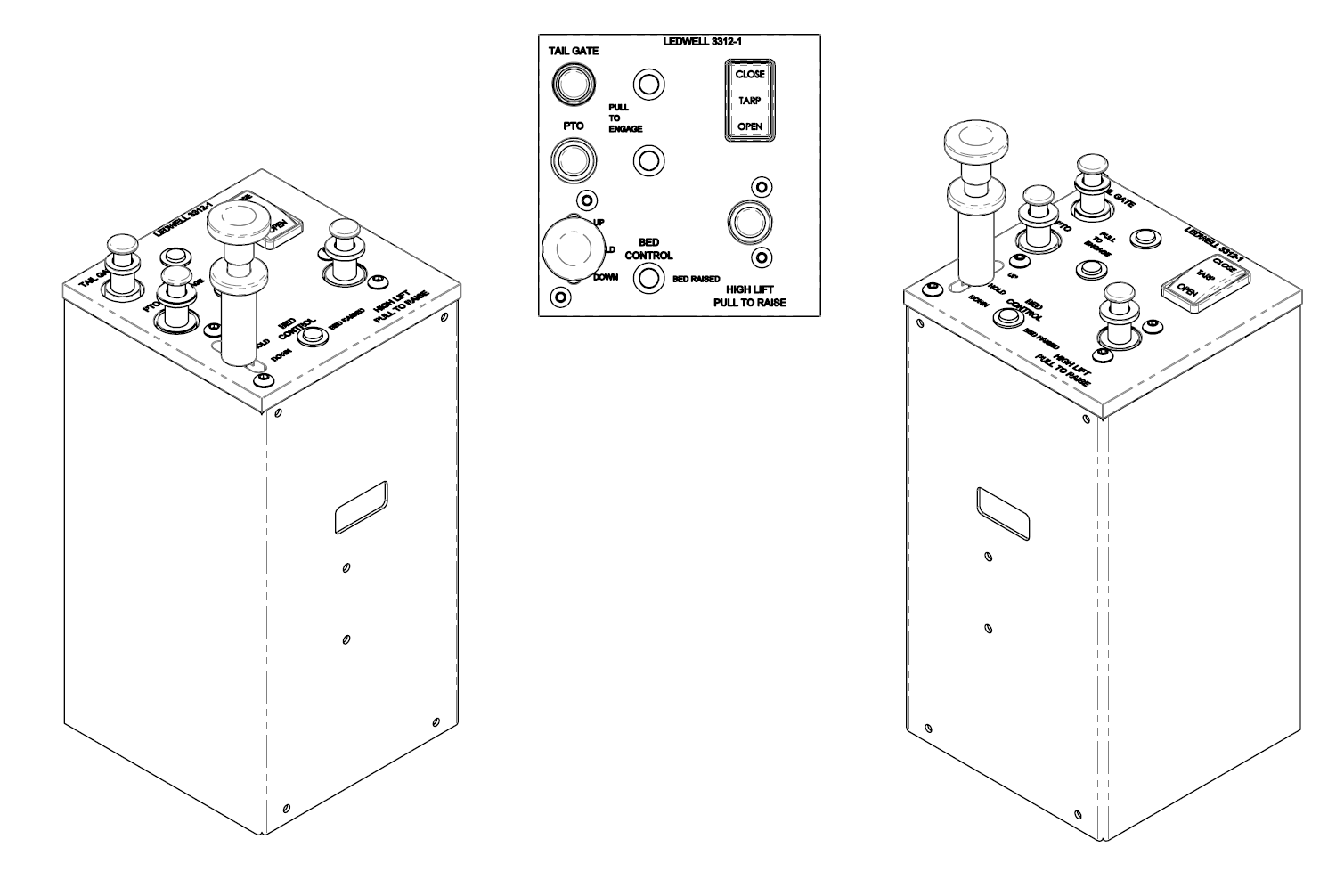

He worked in the Truck Shop the first few years, installing PTOs and rebuilding rebuilt transmissions. Lefty has been driving CDL trucks and delivering equipment to our customers for the last decade.

“I enjoy a good surprise, and my job is like that. I don’t always know where I’m off to each week, but I know it will make a customer happy to see me,” he said about what motivates him to get up and go to work.

Lefty has been married for 21 years to Mary, the love of his life. There are six children and ten grandchildren between the two of them. He loves to spend time antiquing whenever he’s home, especially in Jefferson, Texas.

His dad would always say, “If you take care of the minutes, the hours will take care of themselves.” That has stuck with Lefty over the years. He tries to live those words out each day, from his pre-trip inspection to driving and unloading equipment from trailers.