ASME Code vs Non-Code Tanks: Understanding the Difference

Vacuum tanks are pressure vessels designed to operate under negative pressure conditions. They are commonly used in various industrial applications requiring a vacuum, such as the chemical, pharmaceutical, and food processing industries. There are two types of vacuum tanks: ASME code and non-code. Follow along to understand the difference between ASME code and non-code vacuum tanks.

Step By Step Guide: Pairing Your Wireless Remote

The Ledwell Wireless Remote Kit is convenient for operating equipment from a distance without cumbersome cords or cables. Follow these steps to guide you on how to pair a Ledwell wireless remote with a receiver.

Employee Spotlight: Shannon Bradford

Shannon Bradford has been a valued part of the Ledwell team for 20 years, starting in our Trailer Shop and working his way up to foreman of the Post-Production Trailer Shop. Now, he’s taking on a new challenge as the General Manager of Ledwell East in North Carolina!

Buddy Award Winners

The Buddy Award is an employee recognition program honoring individuals who embody Buddy Ledwell’s spirit. Recipients are celebrated for their unwavering commitment to our core values: Quality, Grit, Legacy, and Family.

These outstanding team members excel in their roles and inspire others. The Buddy Award is a testament to their hard work, integrity, and positive impact at Ledwell.

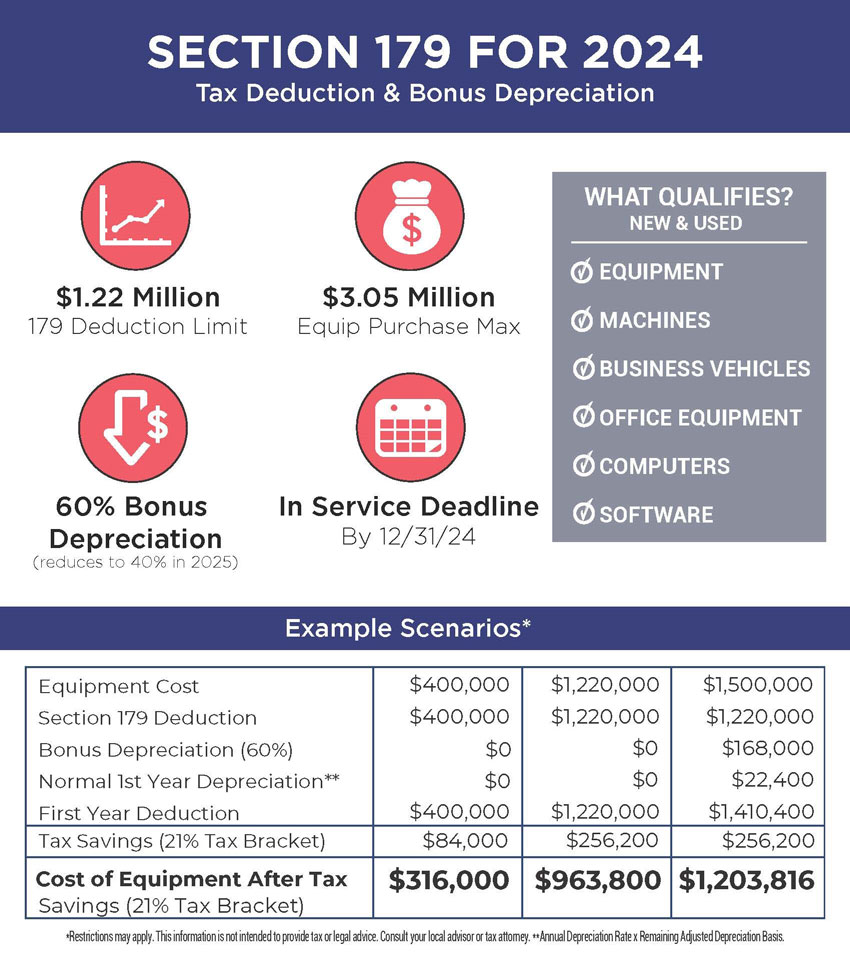

Grow Your Business and Keep More Cash with Section 179

Section 179 Tax Deduction helps businesses save money. It allows companies to subtract equipment, vehicles, and software costs from their taxes if they buy them during the year. Section 179 helps businesses grow by enabling them to buy what they need while keeping more money to use in other ways.

Engineers Sharpen Skills at Cargo Tank Training

Two of our engineers recently attended the NTTC Cargo Tank Test & Inspection Course, held in St. Louis by the National Tank Truck Carriers (NTTC). The course was designed to educate participants on the inspection and recertification of cargo tanks, especially those used for on-road transportation.

Las Vegas

January 12-15

Atlanta

January 28-30

Las Vegas

January 29-February 1

Stay in the know with the Ledwell Newsletter.

Don’t miss out on the latest innovations and happenings. Stay in the loop with the Ledwell newsletter.