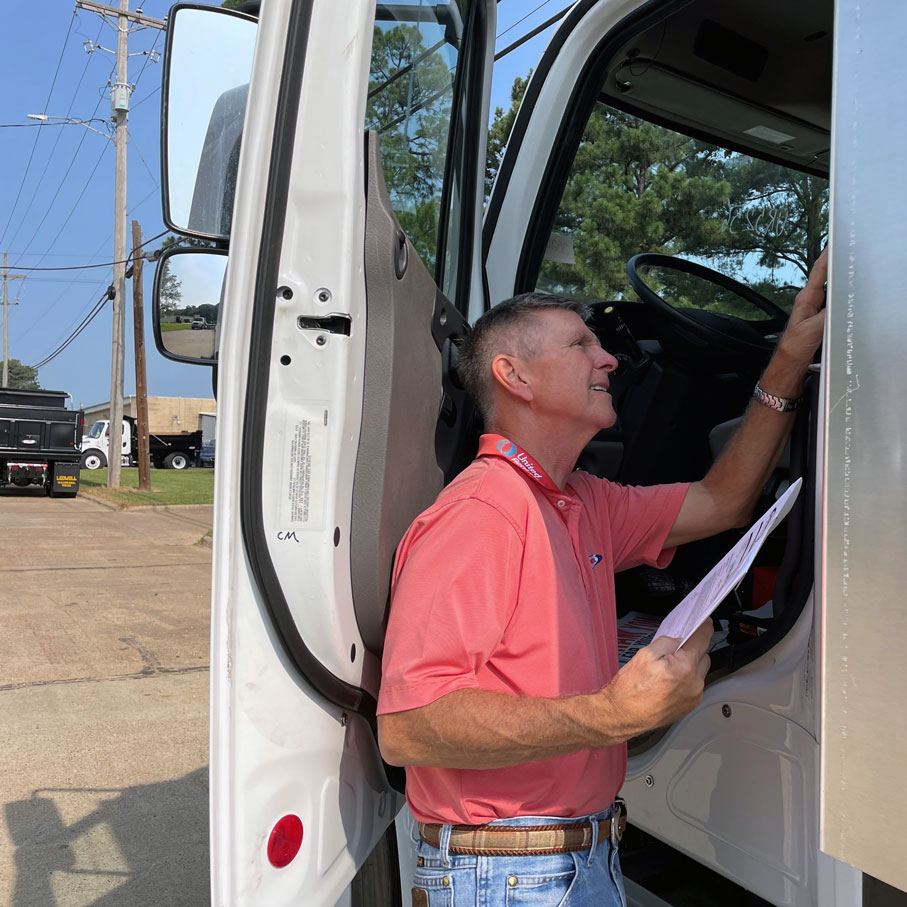

Michael Tucker has been a dedicated member of the Ledwell team for about five years. He started his journey in the Kit Bay, assembling part kits for each bay in the Truck Shop. These kits ensure each order has everything needed to mount a bed to a chassis. Nowadays, although he is still in the Truck shop, Michael focuses on building wet kits and occasionally takes on additional one-off projects.

An essential skill he has picked up at Ledwell is wiring. “Before this job, I never did any wiring. It was a challenge at first, but now I can handle wiring tasks, from relays and PTO switches to lights and fans.”

Michael embodies the Ledwell value of grit and strives for perfection. “I don’t want to see any truck I’ve worked on return from Quality Control.” He describes himself as passionate and hard-working.

According to his foreman, Mike Thomas, “Michael is loyal to his work and is always willing to help others in need. He continuously strives to improve his skills and our product, taking on difficult jobs without hesitation.”

Outside of work, Michael enjoys playing cornhole and creating laser-engraved artwork. He has been with his partner Kayla for 14 years, and together, they have two daughters, Abby and Aubreigh.

Michael also volunteers for the American Foundation for Suicide Prevention (AFSP), helping at events such as their annual walk in November and car show.

Thank you, Michael, for your hard work and dedication. Your commitment to excellence and willingness to help others significantly impact Ledwell.