Nuts & Bolts: Strategic Partnership Helps Companies Grow Together

With 24 dealerships in eight states, Lonestar Truck Group isn’t your average truck dealership.

Ledwell Joins the Stellar Distributor Network

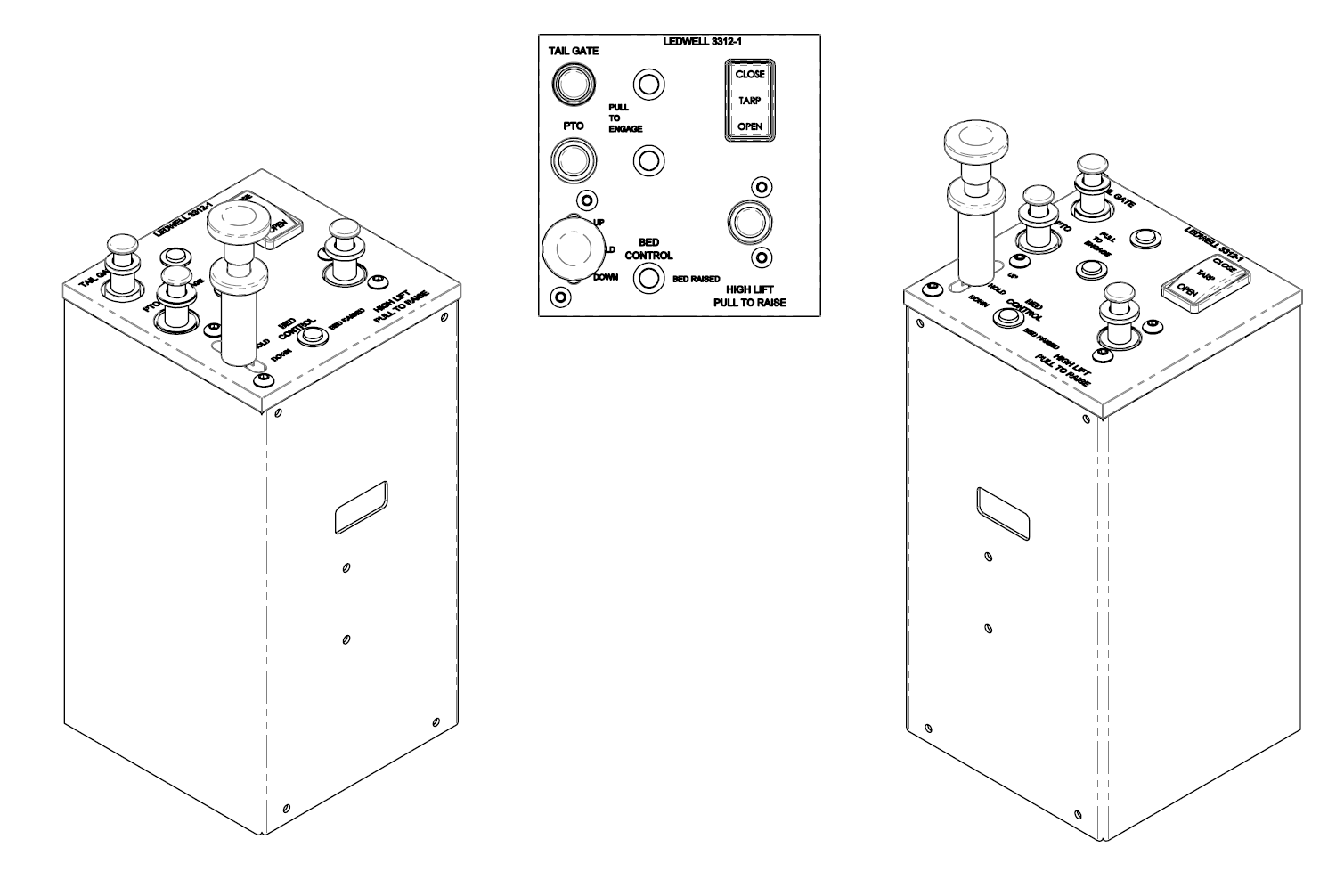

Ledwell is excited to announce it is now a part of the distribution network for Stellar Industries, an employee-owned and operated manufacturer of high-quality service trucks.

Featured Employee: Cliff Harvin, Trailer Shop Foreman

Cliff Harvin believes that having a mindset to learn a trade skill is only half of the equation.

ASME Certification Continues

In 1916 ASME began its program for certification to companies in the pressure equipment industry.

Ledwell Made Mission & Values

At Ledwell, the mission is simple: manufacturing tough, innovative equipment that moves you forward.

Congratulations to our 2022 retirees!

Thank you for everything each of you has done over the years. Your dedication is appreciated.

We wish you a happy retirement.

Jim Greger, 17 years, IT

Mike Harris, 42 years, Feedbody Shop

Chuck Kift, 22 years, Vacuum Tank QA

Andy Squillante, 11 years, Hydraulics

Tereso Tenorio, 15 years, Feedbody Shop

Roberto Torres, 31 years, Truck Shop

Expanding into the Future

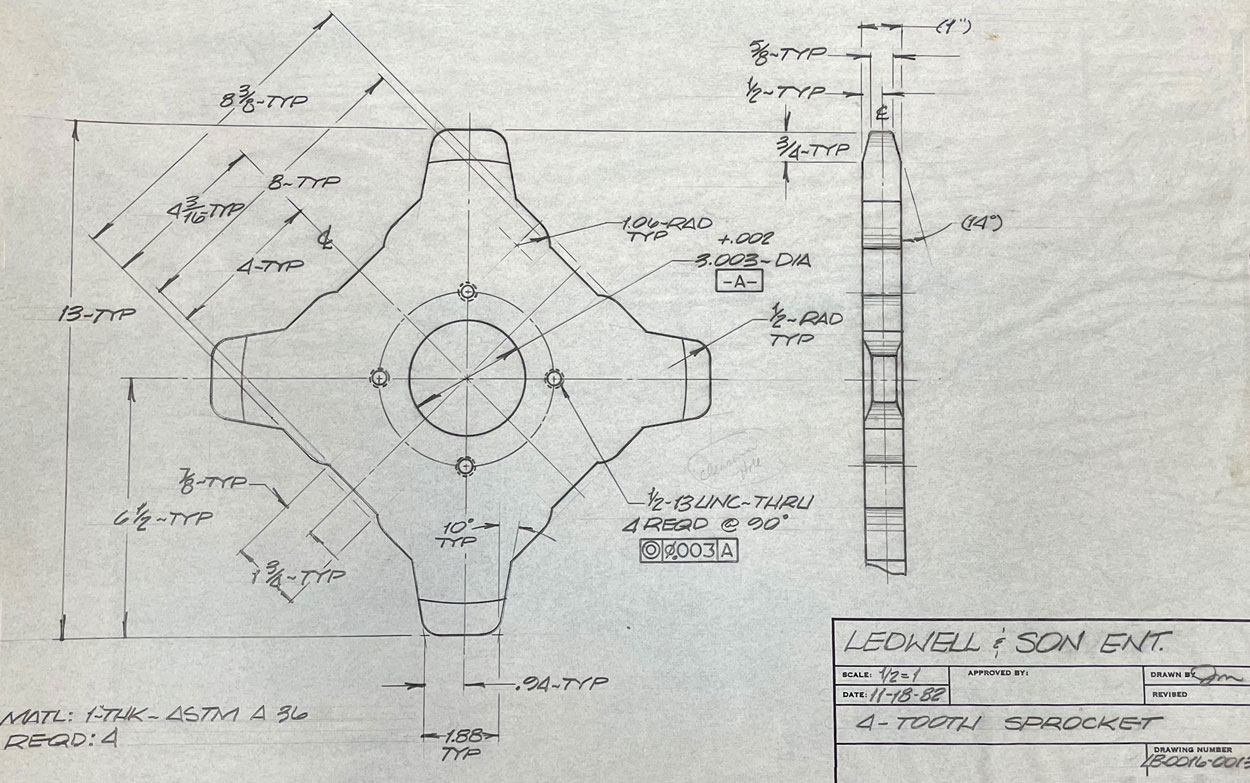

As part of our continuous improvement, we are constantly looking for ways to improve our time on tasks. With the addition of a HAAS ST 45L Lathe to our Machine Shop, we can machine more sizeable parts than ever before. Our cylinder manufacturing process is now more efficient and productive due to this lathe.

Stay in the know with the Ledwell Newsletter.

Don’t miss out on the latest innovations and happenings. Stay in the loop with the Ledwell newsletter.