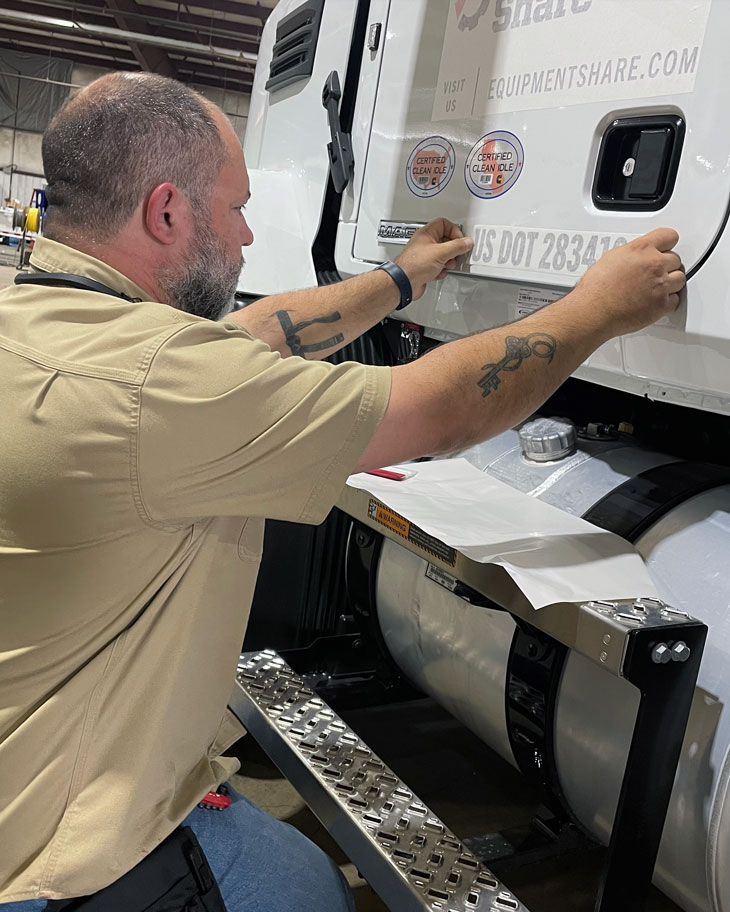

Quality doesn’t stop at the welds or the wiring. Led by Ray Fox, the Graphics Department ensures every piece of equipment carries the Ledwell name with pride. From custom decals to safety labels, this team makes sure our message shows up right every time.

Their job starts with more than just a printer. It begins with understanding exactly what the equipment needs, whether that’s DOT-mandated safety decals or company branding.

Designs are created using industry software, then produced with high-performance printers and cutters that handle everything from small warning labels to large logos.

Printed materials are laminated for protection against weather and wear, helping them last for years.

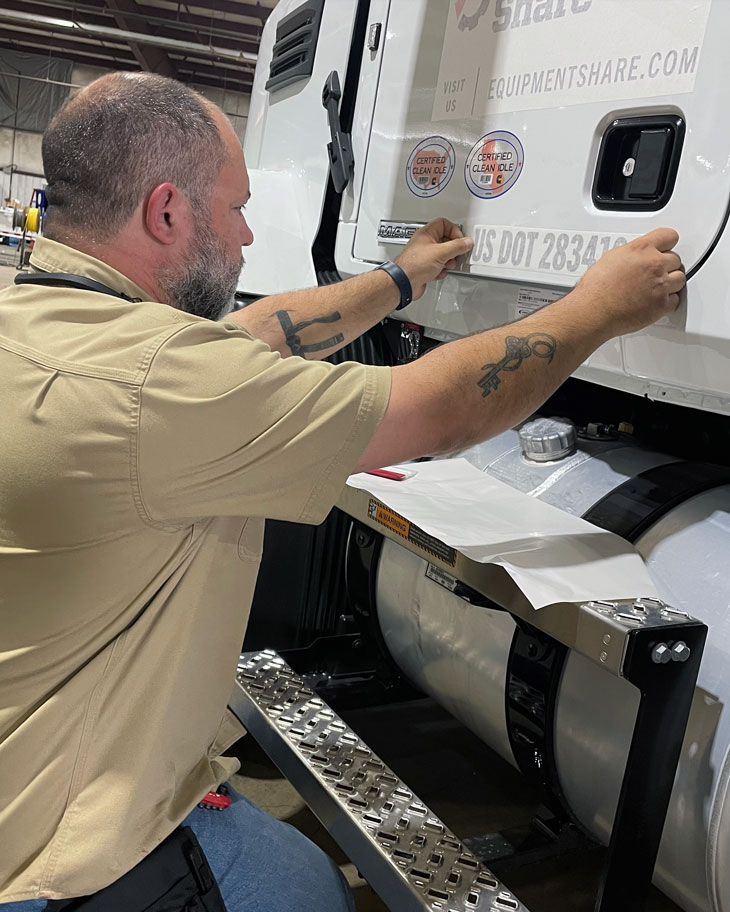

Surfaces are cleaned, and decals are applied using steady pressure and attention to detail for a clean, lasting finish.

What makes the Ledwell Graphics Department different is not just the quality of their materials or equipment, but their attention to detail and the understanding that every application is more than just decoration. It’s a representation of the Ledwell name.

Every label has a purpose. Every wrap tells a story. And every finished piece reflects our commitment to doing the job right.

From start to finish, the Graphics Department plays a vital role. Their work stays visible long after the product leaves the yard, carrying our legacy down the road.