New backpacks, clean shoes, and unopened packs of pencils indicate a new school year as much as the waxed campus floors and the straight rows of unmarked desks do. It is that time of year again—the beginning of fall semester. The newness will certainly wear off, but hopefully, the learning that will occur has a more lasting impact.

As the summer heat persists, students and teachers settle into a year of preparation for the future. Students’ rigorous school schedules might include algebra, chemistry, a foreign language, or Ledwell.

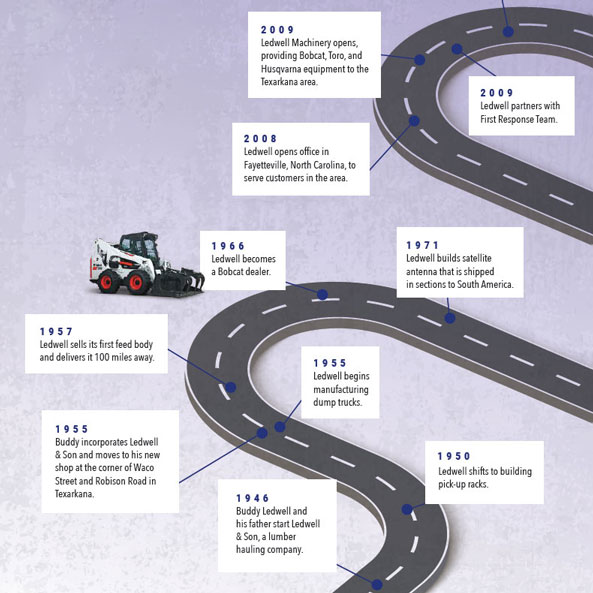

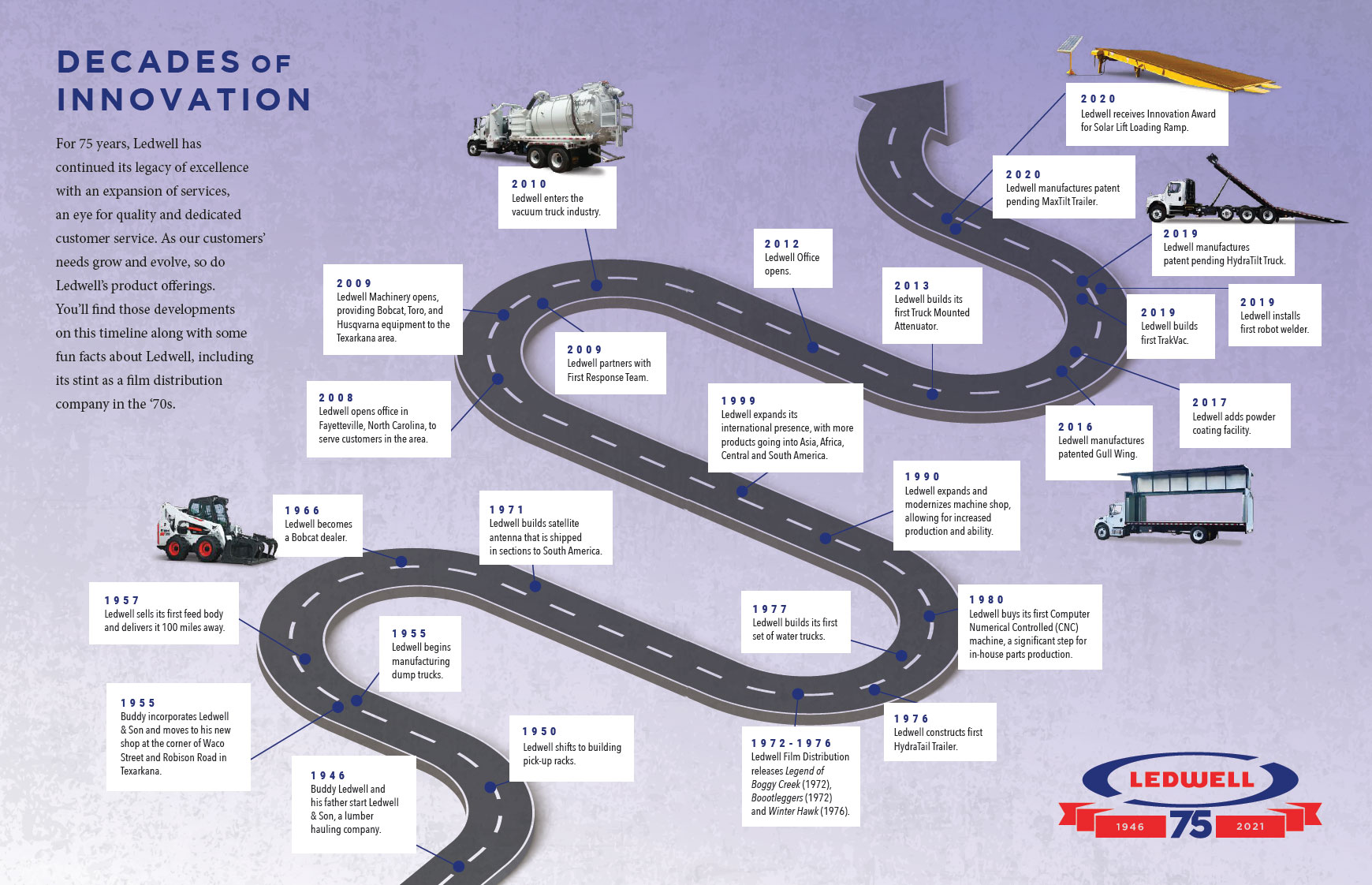

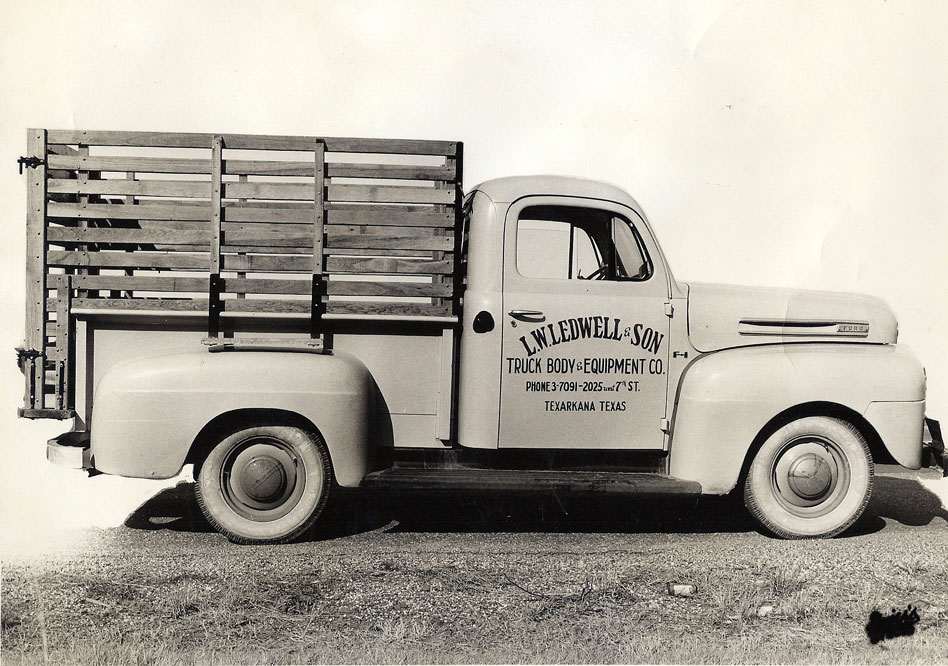

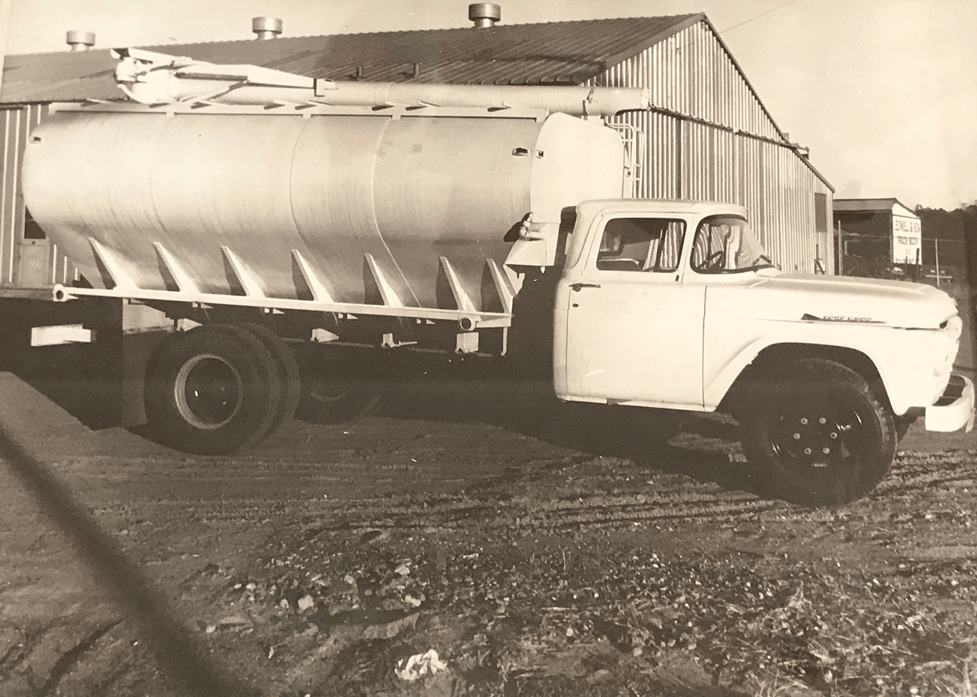

Ledwell is known for manufacturing truck bodies and trailers, but the company also collaborates with schools in the Texarkana area. Sarah Carpenter, Ledwell’s Community Outreach Director, explains, “We’ve worked hard these past few years to create long-term partnerships with organizations and schools within our community.” The goal for this involvement aims to bring awareness about programs that teach important technical, employment, and business skills essential to life after graduation.

In addition to hosting and participating in a multitude of facility tours and career fairs yearly, Ledwell provides internships to high-school students who are interested in exploring their future vocation options. “Internships give [students] the option of skipping the phase of moving from job to job” when deciding on a career path straight after senior year, according to foreman Brad Stringer. Offered during the summer and the school year, internships also “build a potential base of future employees… and a stronger workforce for Ledwell and our surrounding area” Stringer continues.

“Ledwell is currently our largest internship/job placement partner, and we are excited about the opportunity to continue expanding our internship offerings [to] audio/video production students, graphic designers, business students, or any other entry-level [students]…at Ledwell,” states Jennifer Gibson, the Career and Technical Education Director at PGHS. A proud mother shares that her son “is on course for a very promising future, thanks to the collaborative efforts of both of these organizations.”

“We’ve worked hard this past year to create long-term partnerships with organizations and schools within our community. It’s important to provide another option for

Sarah CarpenterCommunity Outreach Director

students who may not attend college after high school.

Our goal is to fill gaps and for students to gain knowledge

of the opportunities right here in Texarkana.”

Interns agree that their coworkers’ patience and willingness to help have greatly impacted their experiences and work ethic at the company. Because of the on-site learning opportunities, one former student of the PGHS CTE program expresses that he is particularly proud of how far his welding skills have progressed at Ledwell. Another intern, Olivia Perry, has combined her love of accounting with a “newfound respect for mechanics” as she navigates the inner workings of a business like Ledwell. “I want to be ready and prepared for a career after I get out of college, and I think being an intern is showing me what a serious job environment looks like.”

Middle and high schools can tour the Betty and Buddy Ledwell Workforce Training Center at Texarkana College to discover other options locally besides going the traditional college route post-graduation. The site includes programs in construction technology, industrial maintenance, and other workforce trades. Admitted high-school graduates can attend day or night classes taught by experts in the field at the state-of-the-art Training Center. Upon completion of the program, participants go into the professional workforce having technical skills and strong work ethic, making them highly sought after by employers.

Ledwell’s educational outreach and partnership with local schools, in Gibson’s words, are “a way of bringing students and businesses together to fill a need for a business and launch students into the workforce to begin their next phase of life after high-school graduation.” With its outreach with local schools, Ledwell shapes more than metal—it shapes futures.