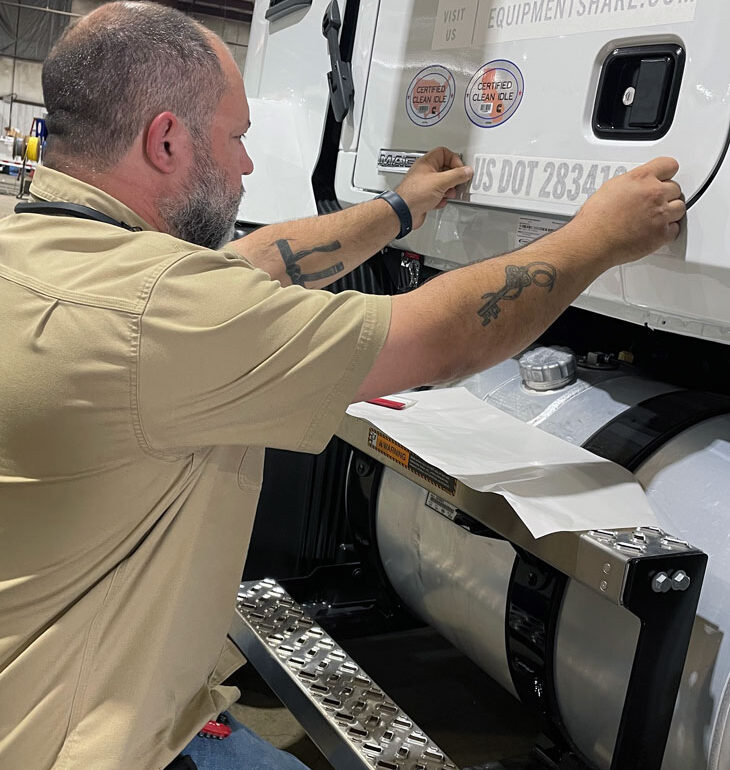

Proper maintenance is vital to ensuring the longevity and performance of your water truck. Ledwell provides comprehensive maintenance guides and FAQs to help equipment owners navigate routine servicing and troubleshooting. From pump output to safety precautions and operating instructions, Ledwell’s resources empower businesses to maximize the efficiency and reliability of their equipment.

Why Maintenance Matters:

Routine maintenance plays a crucial role in your water truck’s overall health and performance. By adhering to a structured maintenance plan, you can:

– Maximize Efficiency: Regular maintenance ensures that your equipment operates optimally, delivering peak performance with every use.

– Extend Lifespan: Proper servicing and care can significantly extend the operational life of your water truck, minimizing the need for costly repairs or replacements.

– Reduce Costs: Preventative maintenance helps minimize downtime and reduces the risk of unexpected breakdowns, saving you time and money in the long run.

– Ensure Safety: Regular inspections and servicing help identify potential issues before they escalate into safety hazards, ensuring a safe working environment for operators and bystanders.

Sticking to a Structured Maintenance Plan:

A structured maintenance plan is the key to optimizing equipment performance and ensuring its durability and reliability. Here’s a step-by-step guide to mastering water truck maintenance:

- Preventative Inspections:

Regularly inspect your water truck for signs of wear and tear, including hoses, valves, and fittings. Look for leaks, cracks, or any damage that may affect performance. Pay special attention to critical components such as the water tank, pump, and spray heads.

- Fluid Checks:

Monitor fluid levels, including water, hydraulic fluid, and coolant, to ensure proper lubrication and cooling of components. Top up fluids as needed and replace any contaminated fluids promptly to prevent damage to vital systems.

- Filter Replacement:

According to manufacturer recommendations, replace filters, such as air, oil, and fuel filters. Clean or replace filters regularly to maintain optimal engine performance and fuel efficiency.

- Greasing and Lubrication:

Grease fittings and lubricate moving parts, such as hinges, joints, and bearings, to prevent friction and wear. For best results, use high-quality lubricants recommended by the manufacturer.

- Electrical System Checks:

Inspect electrical connections, wiring, and components for signs of corrosion or damage. Test batteries and charging systems regularly to ensure reliable operation.

- Brake Inspection:

Check brake pads, rotors, and hydraulic systems for wear and proper function. Replace worn brake components and bleed hydraulic systems as needed to maintain braking performance.

- Tire Maintenance:

Monitor tire pressure and tread wear regularly to ensure safe operation. Rotate and replace worn or damaged tires promptly to prevent accidents and improve traction.

- Fluid Flushes:

Periodically flush and replace fluids, such as coolant, hydraulic, and brake fluid, to remove contaminants and maintain system integrity. Follow manufacturer recommendations for fluid types and replacement intervals.

- Safety Inspections:

Conduct thorough safety inspections, including lights, brakes, steering, and emergency systems, to ensure compliance with regulations and minimize risks of accidents or injuries.

- Documentation:

Keep detailed records of maintenance activities, including dates, tasks performed, and parts replaced. Use these records to track maintenance schedules, identify trends, and plan future servicing.

By following this structured maintenance plan and staying proactive in caring for your water truck, you can maximize its lifespan, minimize downtime, and ensure reliable performance for years to come.

Mastering water truck maintenance is essential for maximizing productivity, efficiency, and safety in your business operations. Ledwell’s comprehensive maintenance guide gives you the tools and knowledge to effectively care for your water truck and keep it operating at peak performance. Invest in regular servicing and preventative maintenance to ensure the longevity and reliability of your water truck, and enjoy years of trouble-free operation.