Are you constantly battling the elements during your deliveries? The Ledwell Gull Wing™ offers the perfect solution to safeguard your cargo from rain, snow, and harsh sunlight. This innovative truck is a game-changer in transportation, providing an advanced alternative to traditional curtain-side trailers and stakebed trucks. With the Gull Wing™, you can be confident that your materials will reach their destination intact and on time.

We understand the importance of protecting cargo from environmental hazards. Our patented Gull Wing is engineered to offer unmatched protection against the elements. Whether transporting sensitive electronics, delicate machinery, or perishable goods, the Gull Wing ensures your cargo remains safe and secure throughout the journey.

Versatility and Customization

The Ledwell Gull Wing™ is not a one-size-fits-all solution. One of its standout features is its versatility and the ability to customize it to meet your needs. The classic model features a 25′ 6″ steel bed length, perfect for accommodating multiple pallets. However, if your business requires a different configuration, Ledwell offers a range of options to ensure the Gull Wing meets your exact specifications.

The unique wing design allows for safe and efficient loading and unloading from both sides of the truck. With center tie-downs, aluminum skin, and a full-function wireless remote, the Gull Wing adds convenience and peace of mind during transport. One of our customers reported a significant increase in on-time deliveries, rising to an impressive 98% from 87% after switching to the Ledwell Gull Wing™ from a flatbed trailer.

Optional Extras for Enhanced Functionality

The Gull Wing doesn’t stop at exceptional performance; it also offers a range of optional extras to enhance its functionality. From a multi-view camera system for improved visibility to low-clearance half-hinge doors and a forklift package, you can customize the Gull Wing Truck to suit your operational needs.

When it comes to protecting cargo during transportation, the Ledwell Gull Wing™ is the top choice. Contact us today to learn how this innovative truck can revolutionize transportation operations.

The Origin of the Gull Wing Truck

Buddy McCulloch, the president of Wholesale Electric, sought a better way to transport products to the company’s branches. The idea for a new solution was born in a local restaurant, Twisted Fork, where Buddy and his lifelong friend Steve Ledwell sketched their vision on a cocktail napkin.

The two companies had grown alongside each other since their fathers founded them after World War II. Wholesale Electric needed a truck with 24 feet of internal loadable space, capable of loading six 4-foot pallets on each side, that could open from the sides and protect the cargo from moisture.

Their collaboration resulted in the Gull Wing Truck, featuring hinged aluminum sides that lift and lower with the push of a button via a central hydraulic system. This design addressed the inefficiencies and weather protection issues of traditional box and stake bed trucks.

Wholesale Electric, a family-owned business based in Texarkana, has expanded to 59 branches since its founding in 1947. It currently operates a fleet of a dozen Gull Wing trucks.These trucks save 30 minutes to one hour of loading and unloading daily, making multiple deliveries daily and significantly improving operational efficiency.

Revolutionizing Logistics Across Industries

The Ledwell Gull Wing truck is making waves across various industries. From ensuring the safe transport of goods to enhancing operational efficiency, the Gull Wing truck is transforming logistics. Let’s explore how different sectors can benefit from this cutting-edge vehicle.

Military and Defense

Reliable logistics solutions are crucial in the military and defense sectors, especially in adverse weather conditions. The Gull Wing truck’s water-resistant design ensures that materials remain dry and protected, enhancing operational reliability in challenging environments.

Wholesalers and Distributors

Protecting products from weather and damage is paramount for wholesalers and distributors. The Gull Wing truck’s specialized design facilitates quick and easy loading and unloading from the sides, reducing handling time and improving overall efficiency.

Building and Construction

Construction businesses benefit significantly from the Gull Wing truck’s ability to transport long, bulky materials like pipes and conduits. The truck’s design allows easy side loading and unloading, making it ideal for job sites with limited space.

Delivery Companies

Transportation and delivery firms, including courier services and e-commerce companies, can greatly enhance their operations with the Gull Wing truck. Its quick-loading capability and weather-resistant design ensure timely and protected deliveries, improving customer satisfaction.

Fleet Management and Logistics Services

Businesses focused on fleet management and third-party logistics providers can optimize their delivery processes with the Gull Wing truck. This innovative vehicle helps streamline operations and improve efficiency by offering specialized services tailored to various industries.

Emergency Services and Disaster Relief

Emergency response and disaster relief organizations can efficiently transport supplies and equipment with the Gull Wing truck, even in adverse conditions. Its durability and weather-resistant features ensure that essential items reach their destination safely, but it can also serve as an on-site delivery platform.

Local Government and Municipalities

Municipalities can use the Gull Wing truck to distribute materials and equipment efficiently. Its design allows for quick and organized loading and unloading, enhancing the efficiency of public service operations.

Environmental Services

Companies in environmental services, such as waste management and recycling, can transport specialized equipment and materials with the Gull Wing truck. Its weather-resistant design and ease of loading and unloading make it ideal for handling various environmental service tasks.

The Ledwell Gull Wing™ truck is a versatile and effective solution for many industries. Its quick loading and unloading capabilities, weather protection, and customizable features make it a valuable tool for any business. As industries evolve, the Gull Wing truck is ready to meet modern transportation demands, providing a reliable option for all.

Comparing Gull Wing Trucks: Choosing the Right Fit

In recent years, the Gull Wing truck has emerged as a leading option in the transportation industry. Its unique design promises to revolutionize how businesses move materials. However, it’s essential to consider all available options before making a major investment. How does the Gull Wing truck compare to its competitors? Keep reading to check out how it stacks up against similar options on the market.

Ledwell Gull Wing™ Truck

The Gull Wing, patented by Ledwell, is known for its innovative design and versatility. Its hinged aluminum sides lift with the push of a button, providing easy access to the cargo bay from both sides. This design streamlines loading and unloading while offering superior protection against the elements, ensuring valuable cargo remains safe and dry during transit. The Gull Wing truck also includes a range of safety features, customizable options, and advanced technology, making it a popular choice for businesses seeking efficiency and reliability.

Curtain Side Trailers

Pros:

– Easy access to the cargo bay from the sides.

– Widely used and available from various manufacturers.

Cons:

– May not provide the same protection against the elements as the Gull Wing truck.

– Curtains are susceptible to wear and tear and may not fully seal the cargo bay.

– Manual operation of the curtains can be time-consuming and cumbersome.

Roll-Up Door Trucks

Pros:

– Quick and easy access to the cargo bay.

– Commonly used in urban environments and well-suited for tight spaces.

Cons:

– Do not provide the same full-length access as the Gull Wing truck.

– Doors can be prone to damage and may not fully seal the cargo bay.

Stakebed Trucks

Pros:

– Hinged or removable panels facilitate loading and unloading.

– Ideal for transporting bulky or oversized items.

Cons:

– Open bed leaves cargo exposed to the weather, even with a tarp.

– Manual operation of the side panels can be labor-intensive and time-consuming.

The Solution

While several options are available for businesses seeking efficient transportation solutions, the Gull Wing truck stands out. Its innovative design, superior protection, and customizable features make it an ideal choice for businesses looking to streamline operations and protect valuable cargo. Ultimately, the right choice will depend on factors such as industry, usage, and budget, but for many businesses, the Ledwell Gull Wing™ represents the future of transportation.

Step-by-Step Guide to Operating a Gull Wing Truck

Operating a Gull Wing truck is straightforward once you know the basics. Here’s a detailed guide to help you navigate the process.

Pre-Operation Inspection

Always perform a walk-around inspection before operating the truck, including a DOT Pre-Trip inspection and checks of specific components.

- Park Safely: The Gull Wing should be parked on a level surface. The brakes engaged, and the wheels chocked.

- Inspect Manual Controls: Check for leaks and maintain the PTO (Power Take-Off).

- Check Hydraulic and Air Hoses: Look for leaks or damage.

- Inspect Flooring: Ensure there is no damage or debris.

- Check Wheels and Tires: Confirm all wheels and tires are intact.

- Verify Lights and Safety Decals: Ensure all warning, work, and indicator lights are working properly and safety decals are visible.

- Look for Structural Issues: Identify loose or missing parts, visible leaks, excessive wear, and structural damage like cracks or rust.

Operating the Gull Wing Truck

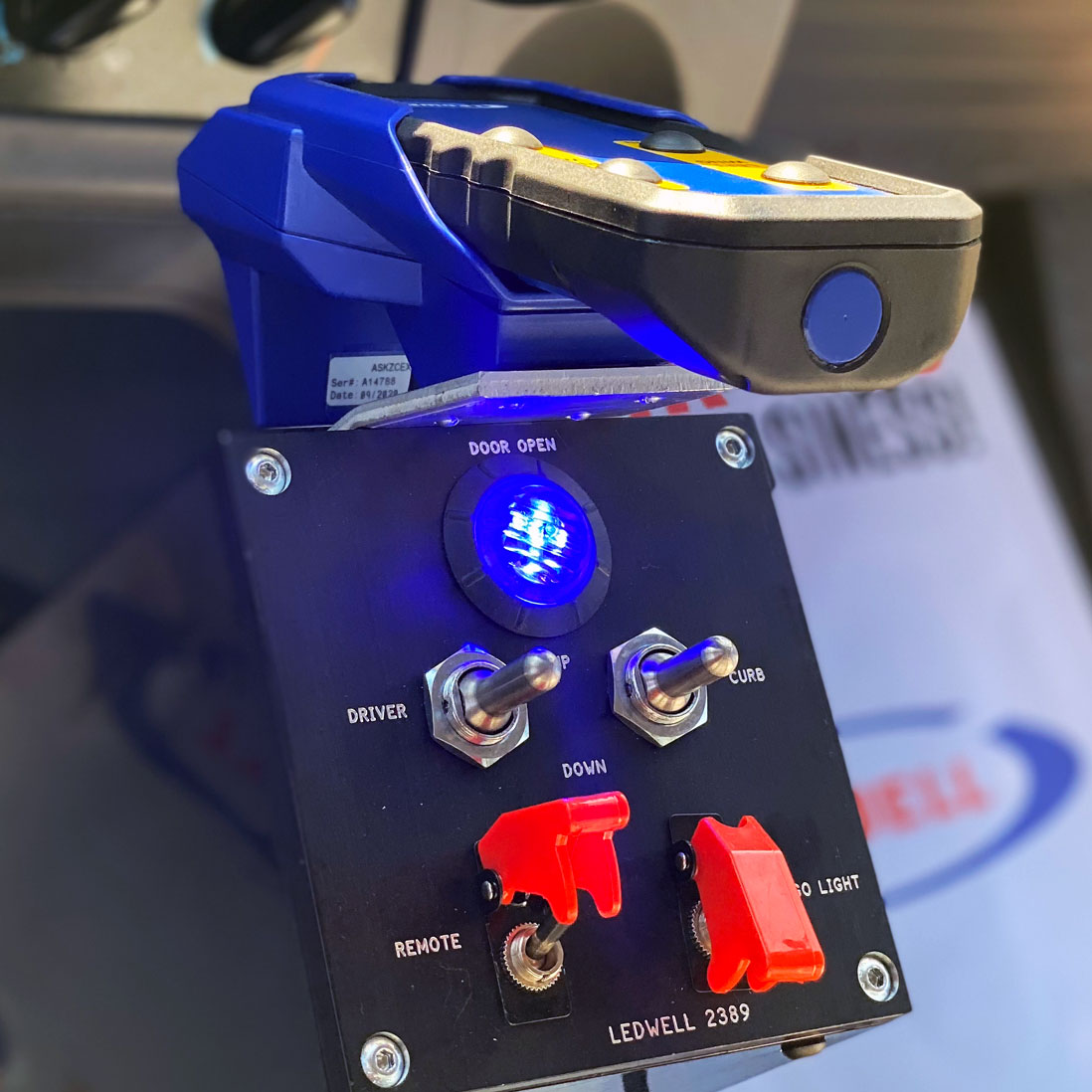

Using In Cab Controls

- Set Brakes and Chock Wheels: Ensure the brakes are set and the truck is in Park or Neutral. Chock the wheels.

- Engage PTO: Inside the cab, engage the PTO to operate the bed.

- Raise/Lower Wings: Use “Driver Up” to raise the left wing and “Curb Up” to raise the right wing. Use “Driver Down” and “Curb Down” to lower them.

Using the Gull Wing Wireless Remote

- Set Brakes and Chock Wheels: Ensure the brakes are set and the truck is in Park or Neutral. Chock the wheels.

- Engage PTO and Activate Remote: Engage the PTO and activate the remote by flipping the switch on at the control tower.

- Raise/Lower Wings: Use “Left Wing Up” and “Right Wing Up” to raise the wings. Use “Left Wing Down” and “Right Wing Down” to lower them.

Loading and Unloading

- Position the Truck: Position the truck at the desired location and set the parking brakes.

- Operate Wings: Follow the steps under Bed Operation to raise and lower the wings as needed. Ensure cargo and all personnel are clear before lowering the wings.

- Transport Mode: Once loaded, push the “Down” button to lower the wings fully. Remove the wheel chocks and disengage the PTO.

By following these steps, you can ensure the safe and effective operation of the Gull Wing truck, maximize its efficiency, and protect your cargo.

Maintenance for Longevity: Preventative Care for Your Gull Wing Fleet

Follow a comprehensive preventative maintenance routine to maintain your Ledwell Gull Wing truck. Regular cleaning, lubrication, and inspections are key to preventing malfunctions and extending the lifespan of your equipment.

Why Routine Maintenance is Crucial

Optimize Performance: Regular upkeep ensures your truck functions at its highest capacity.

Increase Longevity: Consistent maintenance significantly extends the operational life of your equipment.

Save Money: Preventative maintenance reduces downtime and the risk of sudden breakdowns, saving time and money.

Enhance Safety: Routine inspections catch potential problems before they become safety issues.

Committing to a Regular Maintenance Plan

A structured maintenance plan is essential for optimizing your equipment’s performance, durability, and reliability. Follow this guide to master Gull Wing truck maintenance:

Inspection

Start your day with a pre-operational inspection to identify any potential issues. Thoroughly inspect the truck’s components and lubricate all zerks.

– Check cylinders for leaks.

– Inspect all wiring, airlines, and hydraulic lines.

– Examine the truck bed structure and floor for any damage.

– Check the condition of the tires.

– Ensure the lock nut on the cylinder maintains secure contact with the clevis.

Daily Cleaning

Keep your deck clean and dry to prevent debris build-up and corrosion.

Check Fluid Levels

Retract any cylinders to check hydraulic oil fluid levels. If the fluid covers less than half of the sight glasses, fill the hydraulic tank.

Inspect the PTO

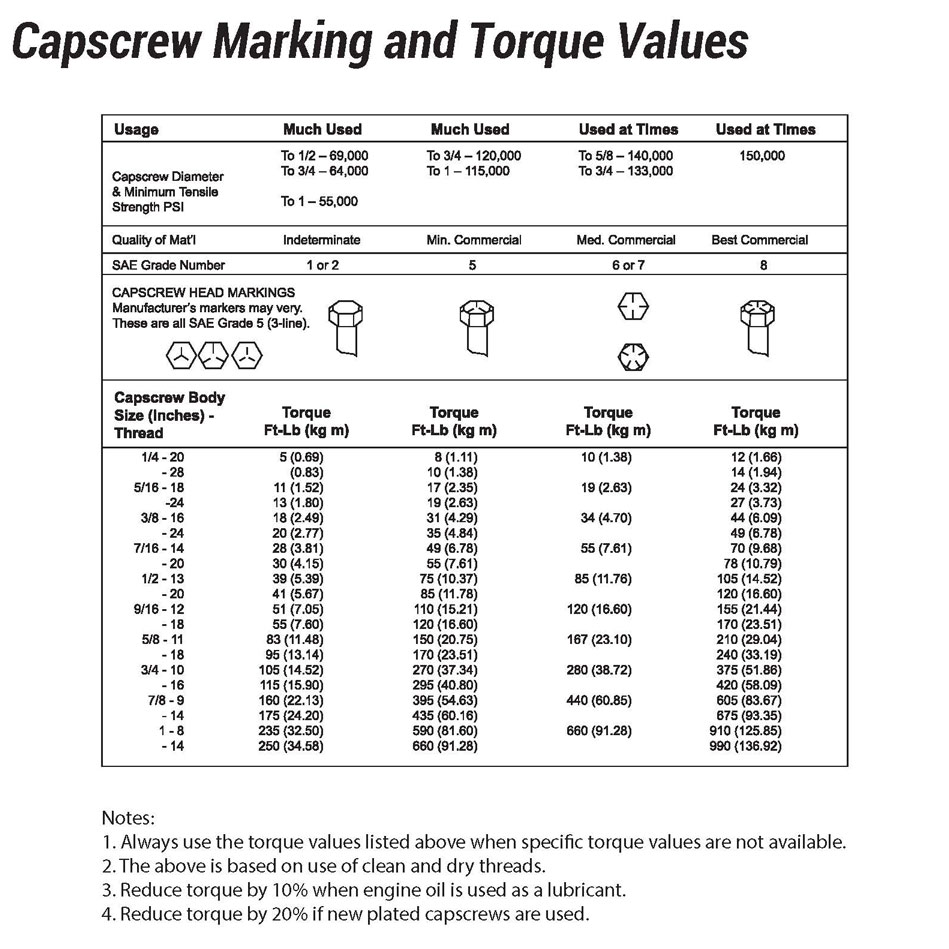

Check the PTO for leaks and signs of high heat. Verify all bolts are tightened properly.

Greasing & Lubrication Points

Regularly grease all zerks, especially at pivot points and the rear of the bed, using GL2 marine-based grease. Some units may have a grease block system with fewer zerks.

Hydraulic Filters

Change the hydraulic filters every six months. Replace the filter cartridge and add hydraulic oil if necessary.

Flushing the Hydraulic System

Flush the hydraulic system annually to remove contaminants.

– Drain all fluids from the hydraulic tank.

– Refill the hydraulic tank according to specifications.

– Start the engine, activate the hydraulic operations, and turn off the equipment.

– Check fluid levels to ensure they reach halfway in the sight gauge.

– Replace the hydraulic air breather cap.

Following this preventative maintenance guide will make sure your Ledwell Gull Wing truck operates efficiently and reliably. Regular maintenance prevents breakdowns and extends the life of your equipment, keeping your operations running smoothly.

Frequently Asked Questions About Your Ledwell Water Truck

Operating and maintaining unique equipment like Gull Wing trucks can sometimes raise questions and uncertainties. That’s why we’ve compiled this list of frequently asked questions to help you navigate your Ledwell Gull Wing Truck.

How do I open the doors?

To operate the doors of a Gull Wing truck using the wireless remote, start by engaging the PTO (Power Take-Off). Then, activate the remote by engaging the switch on the control tower. To raise the doors, push the “Left Wing Up” button to lift the left wing and the “Right Wing Up” button to lift the right wing. To lower the doors, push the “Left Wing Down” button to lower the left wing and the “Right Wing Down” button to lower the right wing.

If the wireless remote is unavailable, you can use the in cab controls on the control tower inside the cab. Begin by engaging the PTO. To raise the doors, push the “Driver Up” button to lift the left wing and the “Curb Up” button to lift the right wing. To lower the doors, push the “Driver Down” button to lower the left wing and the “Curb Down” button to lower the right wing.

What is the best way to load a Gull Wing?

To efficiently load a Gull Wing truck, start by positioning the truck at your desired location and setting the parking brakes to ensure stability. Next, operate the wings by following the Bed Operation steps to raise them on both sides. With the wings lifted, use a forklift to load items from either side of the bed, taking advantage of the truck’s side-loading capability for easy access and efficient loading. Once the loading is complete, prepare the truck for transport by ensuring all cargo and personnel are clear of the wing doors. Push the “Down” button to lower the wings fully. Finally, remove the wheel chocks and disengage the PTO, ensuring the truck is ready for safe and secure transportation.

Is a CDL required to operate a Gull Wing?

You need a CDL (commercial driver’s license) to drive any vehicle that weighs over 26,000 pounds. Depending on the items being transported, additional endorsements might be needed. Check the truck’s GVWR to confirm if a CDL is required or not.

Does Ledwell sell parts for their equipment?

Yes, we do. For a quote on parts for any Ledwell truck bodies or trailers, please reach out to our Parts Department or call 888-LEDWELL (888-533-9355).

Our aim is to provide you with the information needed to get the best performance and longest life from your Gull Wing truck.

If you have more questions or need detailed assistance, please contact our service department. Ledwell is here to support you every step of the way.

Why Ledwell is Your Top Choice for Gull Wing Trucks

If you need a delivery truck that can handle the workload, the Ledwell Gull Wing™ is the top choice. We don’t just sell equipment; we make sure you get exactly what you need when you need it and with unwavering quality.

Here’s the deal: Ledwell has your back when you need a Gull Wing truck fast. No more waiting around—we focus on getting you ready and back to work promptly.

We understand that downtime is costly. That’s why our team at Ledwell prioritizes speed and efficiency. When you have questions or need service, we don’t waste time. We get it done, ensuring you’re back on track before your coffee break ends.

Let’s talk parts. We know waiting for essential components is frustrating. That’s why we manufacture over 85% of our parts in-house and ship out 99% of orders the same day.

But here’s the real kicker: Ledwell doesn’t compromise on quality. Our Gull Wing trucks are built to last. Whether you’re on back roads or city streets, our trucks are designed to endure. That’s the kind of reliability you can count on day in and day out.

At Ledwell, we’re always pushing the envelope, finding innovative solutions to your challenges. Need custom fabrication? We’ve got you covered. Our experts will collaborate with you to design equipment tailored to your unique needs.

The best part? When you do business with Ledwell, you’re not just buying a product—you’re joining a family of hardworking professionals who’ve got your back. We’ve built strong industry partnerships, so you always have the support you need, no matter where your work takes you.

So, why choose Ledwell for your Gull Wing truck needs? Because we’re more than just in the business of selling equipment—we’re in the business of helping people get the job done. We’re behind you for the long haul.

Join the Ledwell family today, and let’s tackle your toughest challenges together.

DOWNLOAD GULL WING EBOOK

Comparing the Best: Rollback Trucks vs. HydraTail Trucks

The Power of a Crash Truck

Caught Working Safe: Making Safety a Way of Life at Ledwell

Built to Stick: Inside the Graphics Department

How Section 179 and Bonus Depreciation Help You Write Off 100% of Equipment Costs