Whether you’re in construction, agriculture, or firefighting, having the right water truck for the job is crucial. Ledwell, a trusted name in the industry, offers a range of top-quality water trucks designed to meet our customers’ diverse needs.

The Versatility of Water Tankers

Different industries rely on water trucks for a multitude of tasks. Ledwell stands out as a leader, providing water tanks optimized for performance and longevity. Let’s explore the top six applications for water trucks and the benefits they bring:

Dust Control:

Water trucks are essential for suppressing dust and airborne particles. They create safer work environments in the construction, mining, and race track sectors. Using Ledwell’s water tanks reduces dust infiltration into machinery, decreasing maintenance costs.

Soil Compaction:

Water trucks are crucial in moistening dry soil in construction and road-building projects, making compaction easier and more efficient. Ledwell’s water tanks facilitate smooth compaction operations while minimizing dust generation and maintaining clean work sites.

Farming:

Agricultural enterprises, vineyards, and orchards rely on water trucks to ensure optimal growth and yield of crops. Ledwell’s water tank trucks support soil conservation efforts and mitigate the effects of drought by supplying water during dry spells.

Street Cleaning:

Municipalities and road maintenance contractors use water trucks to clean streets and sidewalks. These trucks are ideal for reducing slip-and-fall accidents while removing dirt and debris. Ledwell’s water tanks help enhance cleanliness and prevent pollutants from entering waterways, promoting public health and safety.

Fire Control:

Quality water trucks are vital for suppressing wildfires and protecting lives, property, and natural habitats in firefighting and emergency response scenarios. Ledwell’s water tank trucks provide firefighters with a reliable water source and enhance firefighting efforts with quick water deployment.

Potable Water Delivery:

During disasters or humanitarian crises, water trucks deliver clean drinking water to communities lacking access to municipal systems. Ledwell’s potable water trucks support disaster relief efforts and promote public health and hygiene in affected areas.

Elevating Water Truck Performance: Unveiling the Added Benefits

In the world of water trucks, Ledwell offers top-tier models and incorporates many benefits that enhance functionality and reliability. Let’s dive into the added advantages that improve the performance of these industry-leading water trucks:

Bumper/Hose Reel:

– Equipped with a rear hose reel housed within a frame-mounted protective enclosure.

– Features a storage box for side nozzles, suction hoses, and other essential equipment.

Valves & Plumbing:

– Includes an internal primer tank ensuring readiness to pick up water always.

Keel:

– Boasts a quad-bent design with 1,100″ tank support, ensuring structural integrity.

– Features scalloped, interior welded seams to eliminate linear cracking.

– Internal piping is welded before tank installation and tested to withstand up to 120 psi of pressure.

Lights:

– A sealed wiring harness is incorporated for enhanced durability and longevity.

Liner:

– Tanks undergo blasting inside and outside before applying a two-part VOC-free liner.

– The liner boasts a finished thickness of 30 mils, ensuring compliance with potable water standards.

Pump:

– Features an American-built pump with ample stock availability.

– Boasts a 1 ¼” input shaft with a two-bearing system and a 3″ diameter drive-line rated at 500 ft lbs of torque at 3500 rpm.

– Discharges at higher pressures while safeguarding the pump and drive-line during shutdown.

Weight:

– For 2,000 Gallon models, it meets Federal Bridge Law Limits at 33,000 GVW trucks and includes a cab-view water level gauge, essential for 26,000 GVW trucks.

– Incorporates American-made air-operated valves and in-cab controls for added reliability.

Miscellaneous:

– Each tank undergoes water loading and testing in various scenarios to ensure optimal performance.

– Fully baffled tank design includes cross-sectional and longitudinal baffles.

– Ledwell’s commitment to customer service is evident through same-day shipping of parts and prompt phone support.

– Maintains consistent stock availability, ensuring water truck readiness.

– Every water truck is built with uncompromising quality and dedication to customer satisfaction.

Ledwell water trucks excel in performance and reliability and set new functionality and customer satisfaction standards. Experience the difference with Ledwell’s commitment to excellence in every aspect of quality water truck design and manufacturing.

Top-Selling Quality Water Truck Models: Designed for Performance and Reliability

When selecting the right water truck for your business needs, Ledwell offers two top-selling models that stand out for their exceptional performance and reliability. Let’s take a closer look at these industry-leading water trucks:

2000 Gallon Water Truck:

With a 2000-gallon tank capacity and a powerful PTO-driven pump, the Ledwell 2000 Gallon Water Truck is a versatile solution for various applications. Whether you’re tackling dust control on construction sites or providing essential irrigation for crops, this water truck is up to the task. Equipped with in-cab controls, a side spray option, an enclosed hose reel with storage, and multiple filling options, it offers unmatched convenience and flexibility for businesses.

One of the standout features of the 2000 Gallon Water Truck is its ability to deliver consistent performance in any environment. From compact construction sites to expansive agricultural fields, this water truck ensures efficient water distribution with precision and ease. Plus, its protective interior coating provides added durability, ensuring long-lasting performance even in the harshest conditions.

4000 Gallon Water Truck:

For large-scale water projects that demand maximum capacity and efficiency, the Ledwell 4000 Gallon Water Truck is the ultimate choice. With a massive 4000-gallon tank capacity and independent spray functionality, this truck can easily handle the most demanding challenges. Whether fighting wildfires or delivering potable water to disaster-stricken communities, this truck provides unmatched performance and reliability.

Engineered with high-strength steel and a protective interior coating, the 4000 Gallon Water Truck can withstand the rigors of heavy-duty use. Its crosswise and longitudinal baffles ensure stability during transport, while its multiple filling options offer added flexibility for businesses. With DOT-approved lights, reflectors, and conspicuity tape, this water truck prioritizes safety without compromising performance.

Choosing the Right Water Truck for Your Business:

Reliability and performance are paramount when investing in a water truck for your business. Ledwell’s top-selling water truck models exceed expectations, offering unmatched durability, efficiency, and versatility. Whether you opt for the 2000 Gallon Water Truck or the 4000 Gallon Water Truck, you can trust that you’re getting a quality water truck manufactured to deliver results.

With Ledwell’s commitment to excellence and customer satisfaction, you can have peace of mind knowing that your water truck will meet and exceed your expectations. Invest in a Ledwell water truck today and experience the difference firsthand. From dust control to firefighting, Ledwell has you covered with top-of-the-line water truck solutions built to perform every time.

Mastering Water Truck Maintenance

Proper maintenance is vital to ensuring the longevity and performance of your water truck. Ledwell provides comprehensive maintenance guides and FAQs to help equipment owners navigate routine servicing and troubleshooting. From pump output to safety precautions and operating instructions, Ledwell’s resources empower businesses to maximize the efficiency and reliability of their equipment.

Why Maintenance Matters:

Routine maintenance plays a crucial role in your water truck’s overall health and performance. By adhering to a structured maintenance plan, you can:

– Maximize Efficiency: Regular maintenance ensures that your equipment operates optimally, delivering peak performance with every use.

– Extend Lifespan: Proper servicing and care can significantly extend the operational life of your water truck, minimizing the need for costly repairs or replacements.

– Reduce Costs: Preventative maintenance helps minimize downtime and reduces the risk of unexpected breakdowns, saving you time and money in the long run.

– Ensure Safety: Regular inspections and servicing help identify potential issues before they escalate into safety hazards, ensuring a safe working environment for operators and bystanders.

Sticking to a Structured Maintenance Plan:

A structured maintenance plan is the key to optimizing equipment performance and ensuring its durability and reliability. Here’s a step-by-step guide to mastering water truck maintenance:

- Preventative Inspections:

Regularly inspect your water truck for signs of wear and tear, including hoses, valves, and fittings. Look for leaks, cracks, or any damage that may affect performance. Pay special attention to critical components such as the water tank, pump, and spray heads.

- Fluid Checks:

Monitor fluid levels, including water, hydraulic fluid, and coolant, to ensure proper lubrication and cooling of components. Top up fluids as needed and replace any contaminated fluids promptly to prevent damage to vital systems.

- Filter Replacement:

According to manufacturer recommendations, replace filters, such as air, oil, and fuel filters. Clean or replace filters regularly to maintain optimal engine performance and fuel efficiency.

- Greasing and Lubrication:

Grease fittings and lubricate moving parts, such as hinges, joints, and bearings, to prevent friction and wear. For best results, use high-quality lubricants recommended by the manufacturer.

- Electrical System Checks:

Inspect electrical connections, wiring, and components for signs of corrosion or damage. Test batteries and charging systems regularly to ensure reliable operation.

- Brake Inspection:

Check brake pads, rotors, and hydraulic systems for wear and proper function. Replace worn brake components and bleed hydraulic systems as needed to maintain braking performance.

- Tire Maintenance:

Monitor tire pressure and tread wear regularly to ensure safe operation. Rotate and replace worn or damaged tires promptly to prevent accidents and improve traction.

- Fluid Flushes:

Periodically flush and replace fluids, such as coolant, hydraulic, and brake fluid, to remove contaminants and maintain system integrity. Follow manufacturer recommendations for fluid types and replacement intervals.

- Safety Inspections:

Conduct thorough safety inspections, including lights, brakes, steering, and emergency systems, to ensure compliance with regulations and minimize risks of accidents or injuries.

- Documentation:

Keep detailed records of maintenance activities, including dates, tasks performed, and parts replaced. Use these records to track maintenance schedules, identify trends, and plan future servicing.

By following this structured maintenance plan and staying proactive in caring for your water truck, you can maximize its lifespan, minimize downtime, and ensure reliable performance for years to come.

Mastering water truck maintenance is essential for maximizing productivity, efficiency, and safety in your business operations. Ledwell’s comprehensive maintenance guide gives you the tools and knowledge to effectively care for your water truck and keep it operating at peak performance. Invest in regular servicing and preventative maintenance to ensure the longevity and reliability of your water truck, and enjoy years of trouble-free operation.

Frequently Asked Questions About Your Ledwell Water Truck

Operating and maintaining heavy equipment like water trucks can sometimes raise questions and uncertainties. That’s why we’re here to provide clear and concise answers to some of the most common inquiries regarding your Ledwell Water Truck. Whether you’re curious about pump output, safety precautions, or maintenance procedures, we’ve got you covered.

Let’s address these top ten frequently asked questions to ensure you get the most out of your water truck.

What should the output of my water truck be?

Our water pumps deliver about 350 gallons per minute (GPM) at a speed of 2000 RPM with about 55 pounds per square inch (PSI). You can expect a spray pattern 55 feet wide by 30 feet deep and a side spray reaching 65 to 75 feet out. Most power take-offs (PTOs) operate in the 111% to 126% range, with the pump peaking at 2400-2500 RPM.

Can I haul and spray other liquids with my water truck?

Our tanks have an interior coating to protect against corrosion. While it tolerates most chemicals, avoid strong acids, aromatic hydrocarbons, ketones, and chlorinated solvents. Always check the content before loading mixed products.

The pump on my water truck is leaking. How do I fix that?

If your pump leaks, it is working correctly to keep the packing cool. It should drip 40 to 60 drops per minute. Adjust the packing gland ring and the two threaded studs holding it to achieve proper dripping. It’s time to replace the packing if adjustments are at max capacity.

Which Ledwell equipment requires a CDL to operate?

A CDL (commercial driver’s license) is required for any vehicle rated over 26,000 pounds. Depending on the items in transport, a driver might need additional endorsements.

Where can I find information on operating equipment?

Follow these steps or watch this operation video to learn to operate your Ledwell Water Truck correctly.

Where are the extra fuses for the PTO stored?

Equipment mounted on a truck will have extra fuses in the battery box.

How often should I inspect the PTO?

Check the PTO during the pre-operation inspection. Tighten bolts monthly according to the Capscrew Marking and Torque Values Chart.

What size driveline does my water truck use?

Driveline length varies depending on the truck and water tank size. Measure from the pump yoke’s tip to the PTO yoke’s tip for the most accurate measurement.

Where can I get new safety decals for my Ledwell equipment?

We offer decal kits for every piece of equipment we manufacture. Contact our Parts Department for decals specific to your unit.

Does Ledwell sell parts for their equipment?

Contact our Parts Department for a quote on parts for any piece of Ledwell truck bodies or trailers.

Remember, properly understanding and maintaining your equipment are essential for ensuring its longevity and optimal performance. Please don’t hesitate to contact our knowledgeable team at Ledwell if you have further questions or need assistance. Thank you for choosing Ledwell, where quality and reliability meet expertise.

Why Ledwell is Your Go-To Choice for Water Trucks

You’re knee-deep in work on the construction site and need a water truck that can keep up. That’s where Ledwell steps in. We’re not just about selling you a piece of equipment; we’re about ensuring you’ve got what you need when you need it and at a quality that’ll last.

Here’s the deal: Ledwell’s got your back when you’re in a bind and need a water truck fast. No more waiting around for the other guy—we’re all about getting you primed, ready, and back to work in no time.

And hey, we get it. Downtime costs money, plain and simple. That’s why our team at Ledwell is all about hustle. We don’t mess around when you’ve got questions or need service. We get it done, ensuring you’re back up and running before you can finish your coffee break.

Now, let’s talk parts. We know you don’t have time to twiddle your thumbs while waiting for essential components to appear. That’s why we manufacture over 85% of our parts in-house and ship out 99% of orders the same day.

But here’s the real kicker: Ledwell doesn’t mess around when it comes to quality. We build our water trucks to last, plain and simple. Whether you’re on a rugged construction site or a sprawling farm, our trucks can take a beating and keep on ticking. That’s the kind of durability you can count on day in and day out.

At Ledwell, we’re all about pushing the envelope and finding innovative solutions to your problems. Need a custom fabrication? We’ve got you covered. Our team of experts will work with you to design equipment that meets your specific needs, no matter how unique.

But here’s the best part: when you do business with Ledwell, you’re not just buying a product. You’re joining a family of hardworking folks who’ve got your back. We’ve built strong partnerships in the industry, so you know you’ll always have the support you need wherever your work takes you.

So why Ledwell for your water truck needs? Because we’re more than just in the business of selling equipment. We’re in the business of helping you get the job done. We’re behind you for the long haul.

Join the Ledwell family today, and let’s tackle your toughest challenges together.

DOWNLOAD WATER TRUCKS 101 EBOOK

Comparing the Best: Rollback Trucks vs. HydraTail Trucks

The Power of a Crash Truck

Caught Working Safe: Making Safety a Way of Life at Ledwell

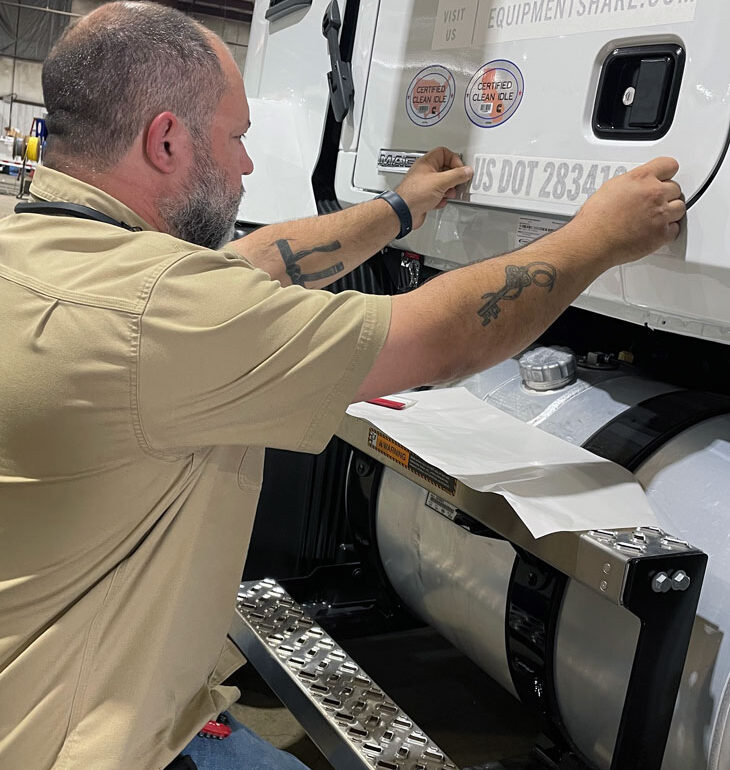

Built to Stick: Inside the Graphics Department

How Section 179 and Bonus Depreciation Help You Write Off 100% of Equipment Costs