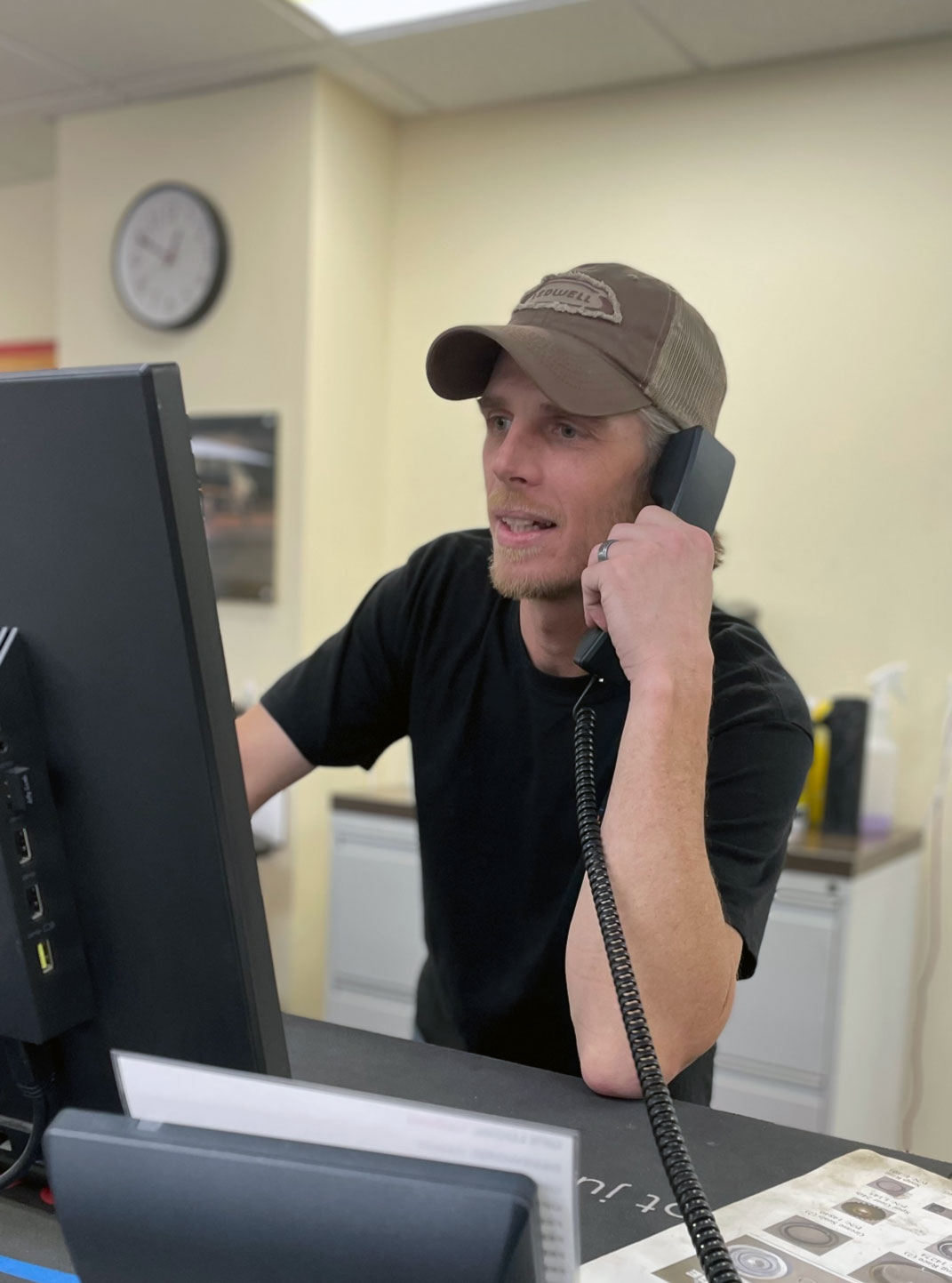

Since 2021, Drake Morgan has played an essential role on the Pattern Torch night shift. As Night Shift Supervisor, he keeps production moving while most of the world sleeps, ensuring every part is cut accurately and ready for the next step by sunrise.

Drake takes pride in how he tackles challenges. When something goes wrong, he does not get discouraged. He leans in, finds the issue, and gets things back on track. His problem solving skills set the tone for his team and show the kind of leadership they can count on.

Many people assume the Pattern Torch crew only moves material on and off the table, but Drake knows the job is far more technical. “You see us taking material on and off the table, but what you do not always see is the machine programming and technical side that tells the torch how to cut the parts,” he explains. His work requires focus, precision, and a strong understanding of the equipment.

During his time at Ledwell, Drake has learned that hard work truly pays off. The value he connects with most is Grit. As he puts it, “No matter how hard the work is, I get it done.” That attitude defines how he approaches every shift, every challenge, and every responsibility.

Drake’s foreman, Tim Snider, sees that effort daily. “He does what I ask and more. Drake steps up to do what needs to be done,” Tim says. Drake stands out because he shows up fully, follows through, and helps wherever he is needed.

Outside of work, Drake keeps busy on his homestead, where he raises goats and rabbits, and he enjoys hunting. His steady, hardworking nature carries through every part of his life.

To Drake, “Ledwell Made” means a quality product that lasts forever. He takes pride in knowing that the parts he cuts help create equipment customers rely on for the long haul.

Thank you, Drake, for your hard work, grit, and commitment. We appreciate everything you bring to the team.