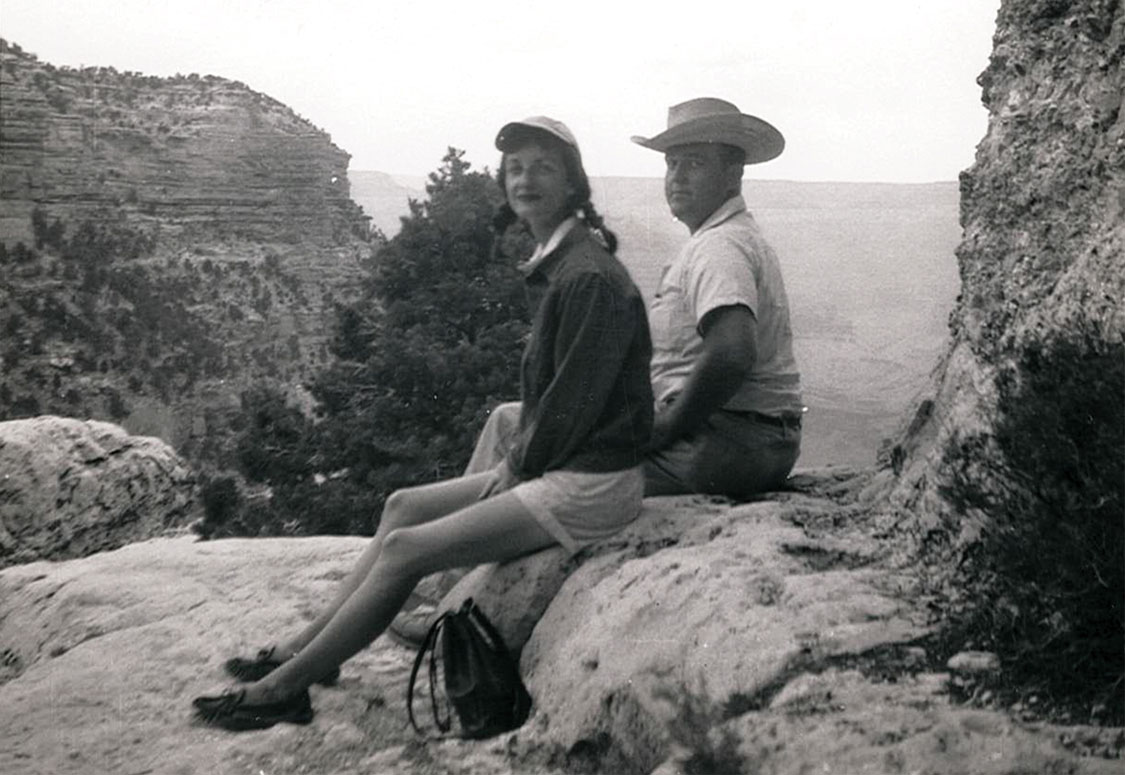

Celebrating 100 Years of Buddy Ledwell

As we celebrate what would have been Mr. Ledwell’s 100th birthday, we’re reminded of the remarkable impact he had on our lives. Though he departed in 2013, his spirit continues to inspire us through cherished memories and enduring lessons.

The Ultimate Solution for Safeguarding Cargo From the Elements

With its innovative design and superior functionality, the Gull Wing™ offers a groundbreaking alternative to traditional curtain side trailers and stakebed trucks, ensuring your materials arrive safely and intact at their destination.

Employee Spotlight: Chris McCormick

Meet Chris McCormick, who began his career at Ledwell in 2011 and has been a crucial part of the team ever since. He is now a Truck Shop Leadman and oversees over 30 bays, where his team mounts truck bodies to chassis.

Buddy Award Winners

The Buddy Award is an employee recognition program honoring individuals who embody Buddy Ledwell’s spirit. Recipients are celebrated for their unwavering commitment to our core values: Quality, Grit, Legacy, and Family.

These outstanding team members excel in their roles and inspire others. The Buddy Award is a testament to their hard work, integrity, and positive impact at Ledwell.

Upholding Quality: Ledwell’s Commitment to Code Welder Testing

In manufacturing, ensuring equipment safety and reliability is crucial, especially in pressure vessels and boilers used in vacuum trucks, where following standards can mean the difference between success and disaster. Ledwell, known for its dedication to quality, incorporates the ASME Code Welder Testing into its manufacturing process to uphold the highest safety and reliability standards.

Elevating Water Truck Performance

In the world of water trucks, Ledwell offers top-tier models and incorporates many benefits that enhance functionality and reliability. Let’s dive into the added advantages that improve the performance of these industry-leading water trucks:

Cutting-Edge Precision: New Laser Enhances Production

Ledwell is excited to announce the integration of a state-of-the-art Messer Laser into production, which will revolutionize cutting processes with unparalleled precision and efficiency.

Michael Applebaum, who operates the new laser, highlights its remarkable impact on cut quality across various materials. “It has improved cut quality tremendously on many different materials,” he says. The laser easily handles different thicknesses, using nitrogen for clean, fast cuts on thinner materials up to 3/8 inch and oxygen for slower, precise cuts on thicker materials.

Stay in the know with the Ledwell Newsletter.

Don’t miss out on the latest innovations and happenings. Stay in the loop with the Ledwell newsletter.